500 hours of testing. This is how long the AcroMat 100-Cleanroom Series anti-fatigue mat had to be evaluated, without contamination, in order to earn Class 5 Cleanroom Certification.

Why is anti-fatigue mat cleanroom certification important? What does the process involve? Most importantly, how can you be certain your cleanroom mats are preventing contamination? We answer each of these questions below.

Short on time? Find a brief summary and infographic of these test results and other OSHA-accredited, third-party lab testing data here.

What is a Class 5 Cleanroom?

A cleanroom is a controlled environment that filters out pollutants like dust, aerosol particles, and airborne microbes to create the cleanest environment possible. Cleanroom classifications are determined by the number and size of particles allowed "per volume of air" over time. As the classification goes up, requirements get more stringent. In the simplest of terms, Class 5 (ISO-5) is the 3rd most "clean" environment.

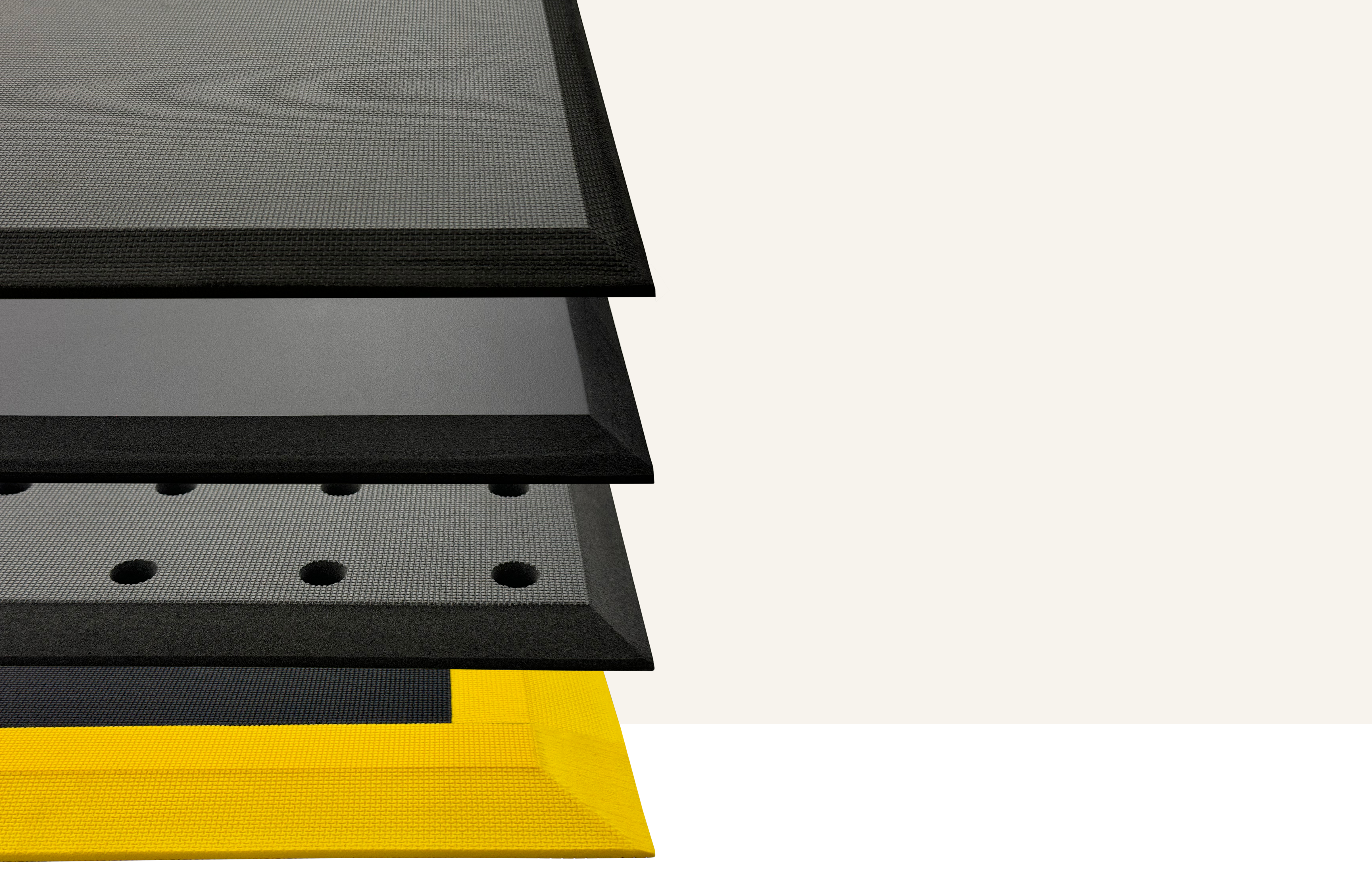

This custom 100-Cleanroom Series mat for Colder Products Company provides three unique benefits. The Class 5 Cleanroom Certification ensures the mat doesn't shed or emit particles, the custom shape provides a seamlessly fit within the workstation, and the ADA-Compliant yellow borders on entry/exit points support smooth on/off transitions.

This custom 100-Cleanroom Series mat for Colder Products Company provides three unique benefits. The Class 5 Cleanroom Certification ensures the mat doesn't shed or emit particles, the custom shape provides a seamlessly fit within the workstation, and the ADA-Compliant yellow borders on entry/exit points support smooth on/off transitions.

What are cleanroom certified anti-fatigue mats?

Cleanroom certified anti-fatigue mats protect vulnerable products and people as a result of the materials they are made of. Specifically, the AcroMat 100-Cleanroom Series is made from molded, closed cell, nitrile rubber. Through testing and certification, this material has proven not to shed or leave foreign material behind as the mat ages. The 100% nitrile material is also folded in with silver ions during the molding process to ensure it’s also antimicrobial.

This AcroMat 100-Cleanroom Series mat, Class 5 Cleanroom Certified, for Medtronic features circular cutouts to prevent prolonged damage from chairs along with 20-degree yellow borders for when chairs need to roll on to the mat.

Why is cleanroom certification important?

Companies need to know with certainty their mats will not contaminate the work area by harboring bacteria or shedding foreign particles. Official certification ensures this through careful, rigorous, third-party testing in cleanroom environments. If even one sample shows sign of vulnerability during testing, the mat “fails” and won't be certified.

In order for our 100-Cleanroom Series mat to earn certification, we were asked to submit five mat samples, with each being assessed for a minimum of 100 hours – 500 hours in total.

The cleanroom anti-fatigue mat certification test period is a minimum of 100 hours for each mat to ensure repeatable results and eliminate random abnormalities.

One-piece custom designs. Thousands of square feet. Class 5 Cleanroom Certified. Take a tour through this Fortune 500 medical device manufacturer's 100-Cleanroom Series mats.

What does the cleanroom certification process entail?

"To test and certify a mat, it's necessary to test them in Static and Dynamic situations," shares Acorn Industries (formerly Ultraclean Laboratories), the company that led the testing process on behalf of AcroMat. "We require five mats for these tests. The Static tests investigate the mat material in our quality control Laboratory using two of the mats to determine the mat’s ability to remain whole and not emit particles."

"The Dynamic tests are performed in our own cleanrooms using the other three mats under actual cleanroom personnel traffic and wear patterns. The test period is a minimum of 100 hours for each mat to ensure repeatable results and eliminate random abnormalities."

The key is consistency. Mats are tested for 100 hours each to make certain any vulnerabilities or inadequacies are rooted out and discovered.

This AcroMat 100-Cleanroom Series mat was designed for Boston Scientific. In addition to being cleanroom certified, the anti-fatigue mat is covered under a Lifetime Warranty that guarantees it will never sink, flatten, lose its cushion, or curl along the borders.

Summary & Key Takeaways

As you explore cleanroom anti-fatigue mats and consider an investment, it's important to do your due diligence to ensure your people and products are protected. Before making any purchase, follow these five steps:

1. Uncover the certification level of the mats you’re considering.

2. Ask for a copy of the certification to ensure validity.

3. Ask for details about the testing and certification process. How did they get their mats certified? When? Do they have to re-certify after a certain number of years? Why did they receive the certification level they did? What did the testing process involve?

4. Make sure your mats will fit. Can the cleanroom mats you're considering be custom-cut to fit your complex layouts, or are you stuck with rigid standard sizes?

5. Get a sample mat and put it to the test over multiple weeks. Know with certainty you're getting a material that not only protects your cleanroom, but provides the comfort and durability your people need.