CASE STUDY

Red Wing Creates New Anti-Fatigue Mat Standard

Challenge

As EHS Specialist over the company's manufacturing plant in Red Wing, Minnesota, Jolene Moldenhauer is tasked with elevating health and safety on behalf of her team. She saw an opportunity to transform both by "standardizing" their approach to anti-fatigue mats.

"I was sick of having random anti-fatigue mats spread throughout the place," says Jolene. "I wanted 1-2 consistent styles we knew would work."

Specifically, Jolene set out to unite the facility's approach under a single strategic plan; one that would reduce injury risks, eliminate confusion from the buying process, and give everyone peace of mind for the long term.

We have used AcroMat in our manufacturing facilities over the last 2 years, and the mats are holding up well despite heavy traffic. The service is reliable, orders are received very timely, and the AcroMat team is always willing to come on-site when we need help.

Solution

Creating an Anti-Fatigue Mat Standard

After trialing multiple sample mats and gathering feedback from her team, Jolene worked closely with AcroMat to bring the high number of "random" mats down to two specific styles she knew with certainty would perform.

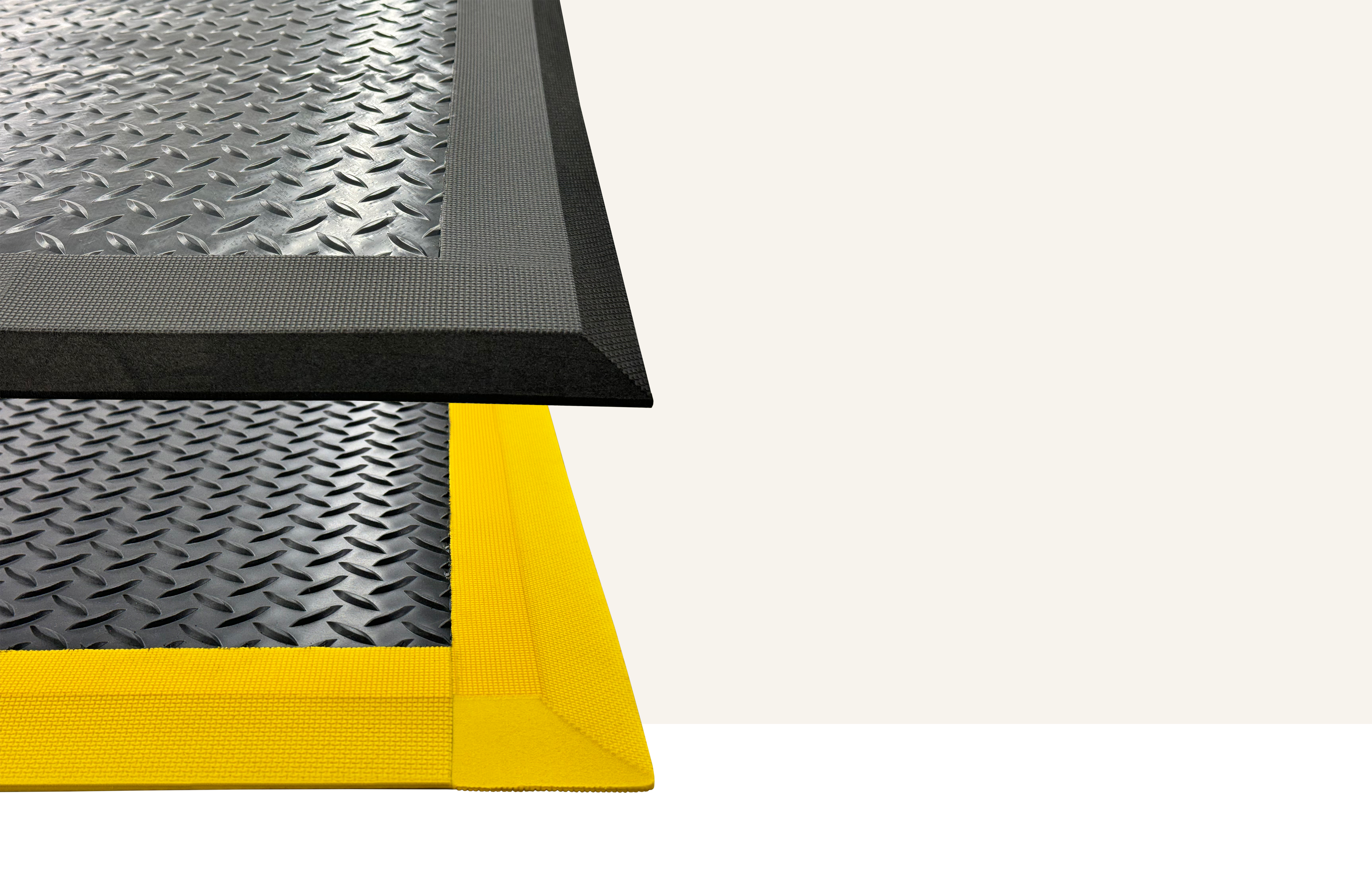

The two styles are the AcroMat 100-1 Series and NitriTuf Diamond Series, both with ADA-compliant yellow borders.

Jolene and AcroMat then created and instituted a Standard Work Instruction (SWI); a formal, easily communicated and sharable document that has given employees across the facility a roadmap to follow when new mats are needed – saving time, eliminating confusion, and reducing overall costs.

Reducing the number of mats from 10+ down to two has also led to:

- Consistent traction

- Consistent comfort

- Consistent surfaces

- Consistent materials

- Consistent warranties

- Consistent performance

- Consistent life expectancies

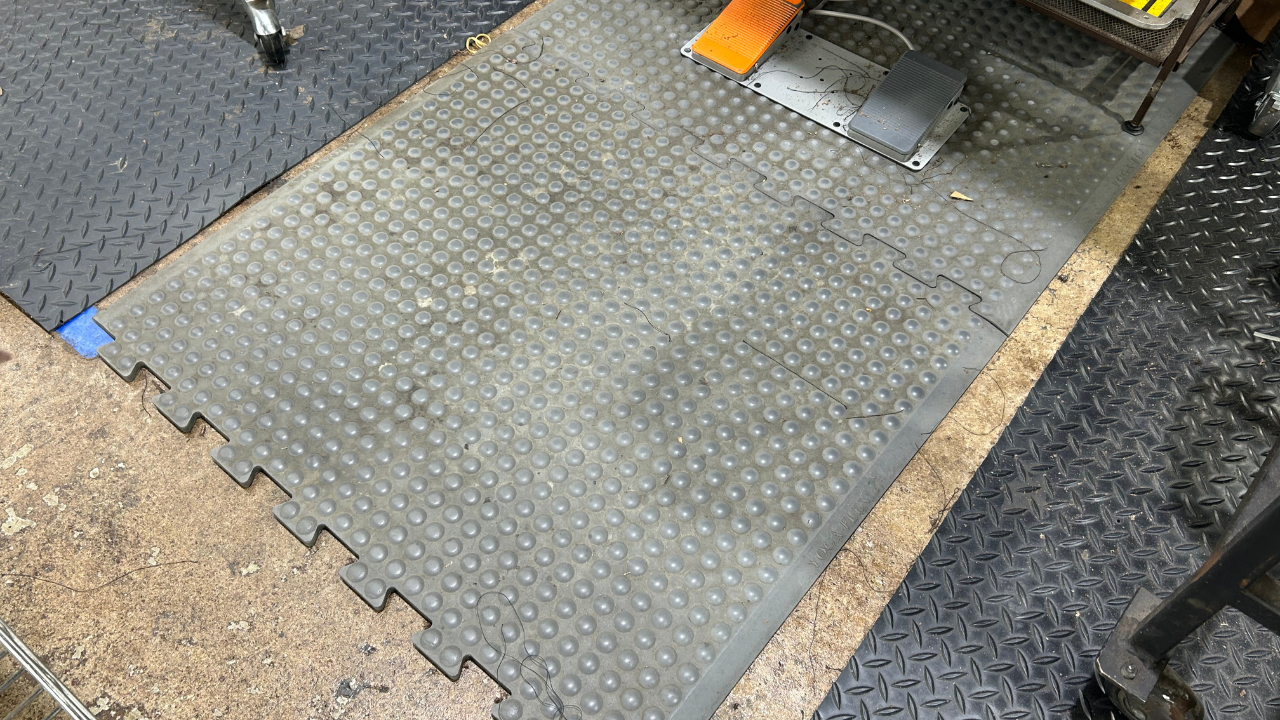

Before: Red Wing Shoe Co. had an array of "random" anti-fatigue mats spread throughout the facility, creating a host of slip, trip, fall and ergonomic hazards.

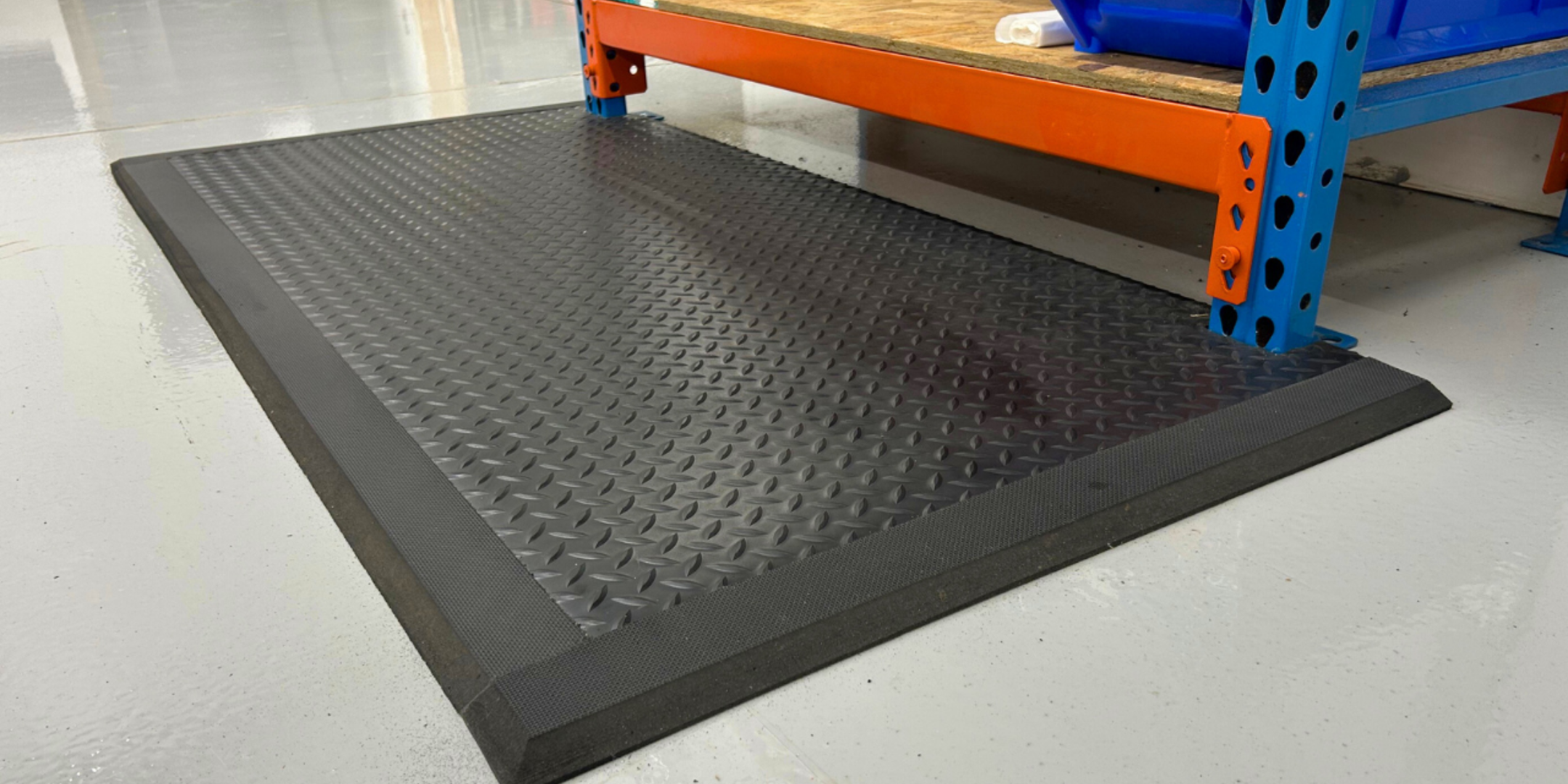

After: Red Wing Shoe Co. replaced the 10+ styles of box-store with two proven mats with AcroMat, in turn reducing costs and confusion, improving durability, and elevating safety facility-wide.

50% Reduction In Pain & Fatigue

Standing for long hours without relief, especially on harsh surfaces like concrete, causes blood to pool in the legs and feet. This can progress to painful varicose veins, inflammation and swelling. It also causes joints in the lower back, hips, knees, and feet to stiffen and lock up.

Anti-fatigue mats work by promoting subtle foot movements, which helps the lower leg muscles contract/expand to improve circulation.

Pure nitrile and premium NBR rubber foam, the materials that makeup the AcroMats used by Red Wing Shoe, are unique in that they never flatten or lose their ergonomic cushion. With a medium-soft durometer rating, the materials have:

- Reduced pain and discomfort by 50% compared to hard surfaces

- Reduced impact injury risks by 70% compared to hard surfaces.

Improvements to Shoe Production

Red Wing Shoe operators make the highest quality work boots and shoes on the market. To do so, they're constantly dealing with solvents, wax, grease, staples, rubber, and leather.

Many of the Red Wing Shoe's AcroMats have been in use for 2+ years. In a facility that operates 24 hours a day, 5 days a week, this has amounted to 11,000+ hours of uninterrupted support from their mats. Despite the heavy use and constant exposure to harsh products, the closed cell, impervious materials continue to endure without failure or interruption.

Elimating Trip Hazards At Ground Level

Red Wing Shoe has a fast-paced environment; operators move back and forth across their workstations. Slips, trips, and falls are the No. 2 most common workplace injury, and curling anti-fatigue mat borders are a key contributor. To support their fast-moving operators, Red Wing Shoe needed mats that would remain flat and not curl along the borders.

AcroMat's exclusive cut-and-bond mat design, combined with premium closed cell materials, has led to a guarantee (and warranty) that Red Wing Shoe's anti-fatigue mats will not curl, eliminating a critical safety hazards and ensuring seamless on/off transitions for employees.

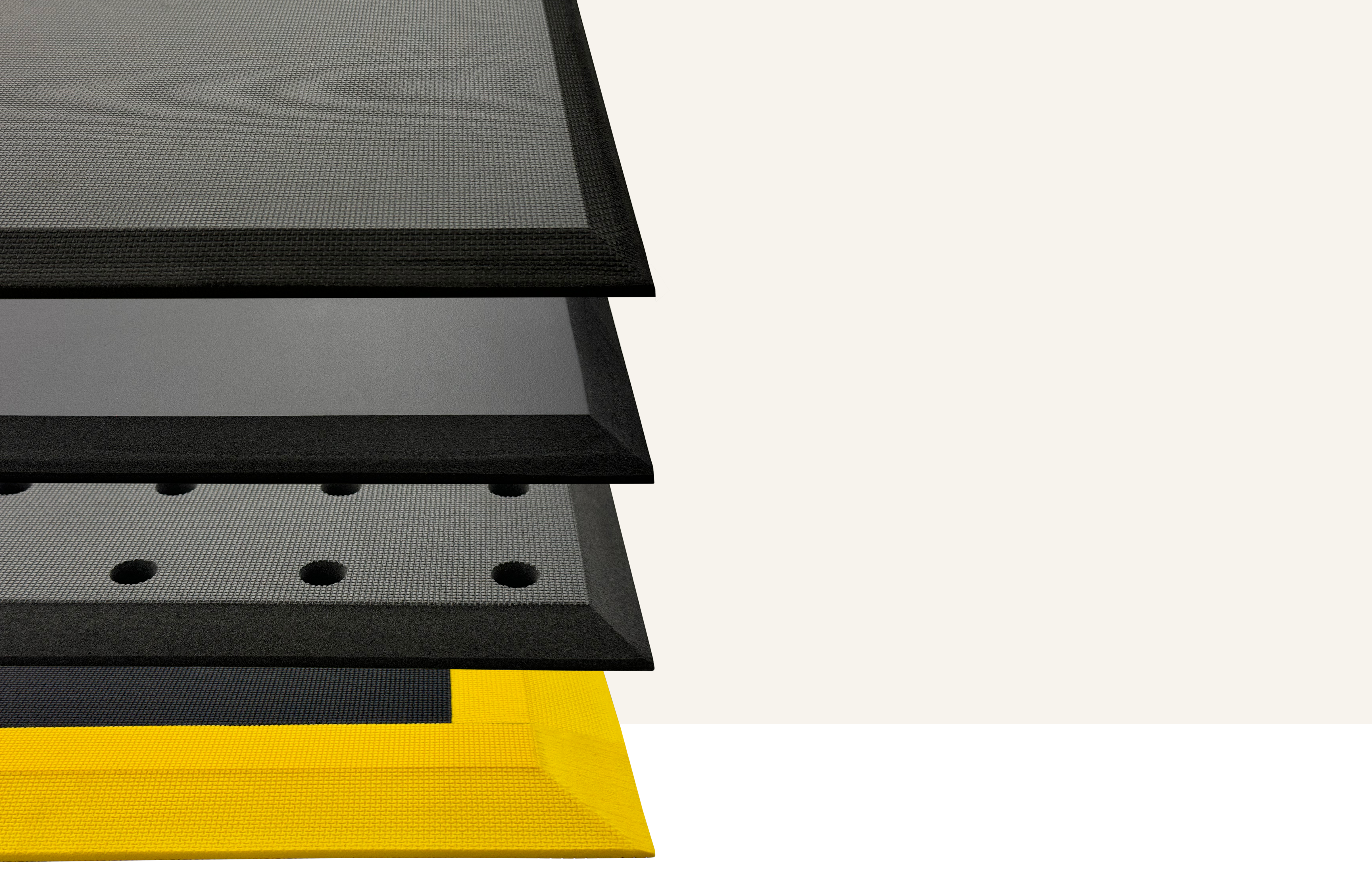

100-1 Series: Red Wing Shoe uses two styles of AcroMat, the 100-1 Series and the NitriTuf Diamond Series. The 100-1 is chemical resistant, guaranteed to never compress, and backed by a full-replacement warranty.

NitriTuf Diamond Series: The NitriTuf Diamond Series is the only diamond-plate mat available guaranteed not to curl, helping Red Wing Shoe eliminate a previously critical trip hazard.

Featured Products

SOLUTIONS BUILT FOR YOUR ENVIRONMENT

100-1 Series

LEARN MORE

NutriTuf Diamond Series

LEARN MORE