CASE STUDY

TruStile Doors Overcomes Injury with Custom Anti-Fatigue Mats

Challenge

An operator with TruStile Doors, a Marvin Windows brand, suffered a rolled ankle when he tripped over two disconnected anti-fatigue mats that were laid next to each other. The operator needed medical treatment and physical therapy, and missed multiple weeks of work, while the company lost money, time and critical production.

Previously, the team at TruStile Doors was buying long rolls of anti-fatigue mat and hand-cutting them to fit individual work areas. This approach led to the serious injury.

In response, EHS Manager Andy Grunhovd and his team partnered with AcroMat to replace all of the hazard mats with custom anti-fatigue mats seamlessly designed to fit each workstation. This approach eliminated all hazards caused by the pieced-together mat approach and set operators up for long-term success.

The new AcroMats have been a real win for our feet and backs. We don't trip anymore either.

Before: Operators were hand-cutting roll mats for their work areas, with the gaps and constant on/off stepping leading trip and fall injury that took an operator away from work for several weeks.

After: Trustile re-made their facility with one-piece custom AcroMat mats designed to fit each workspace. The precise designs eliminated gaps, trip hazards, and ergonomic inconsistencies.

Solution

Key Results:

- Permanently eliminated mat-related slip, trip, and fall risks

- Eliminated edge-standing and constant on/off stepping

- One-piece custom mats designed for each workstation

- Moved from buying mats every 6 mos. to every 5+ yrs.

- Custom mats for entire facility cost less than the injury

- Pain and discomfort reduced by 50%

- Fall-related impacts reduced by 70%

Injury Prevention

Previously, TruStile operators were hand-cutting long rolls of mat into individual pieces then laying them throughout each workstation. This was "easy," according to Andy, but led to gaps between mats, missing beveled edges, trip hazards, constant on/off stepping, ergonomic issues, and the subsequent ankle injury; an operator tripped moving from one mat to another pieced next to it.

AcroMat's one-piece custom anti-fatigue mat designs, specifically measured and designed to fit the complex layouts of each workstation, eliminated gaps in coverage, edge standing, and the need for operators to constantly step between individual anti-fatigue mats.

Instead of hazards, they now have a consistent surface, traction and ergonomic support, and the glove-like fit keeps the mats firmly in place.

In addition, nitrile anti-fatigue mats have proven to reduce head and hip fall-related impacts by up to 70%. By covering entire workstations with nitrile custom mats, if there ever is another fall, operators will land on cushion rather than cement.

Ergonomic support

The TruStile team’s previous mats were "going flat in 6 months." Beyond having to buy new mats, which stretched the budget, workers were uncomfortable. They were, in effect, standing on hard concrete and increasing both fatigue and MSD injury risks.

The previous mats were made from PVC foam and PVC-nitrile blends, which lose their cushion over time. The custom 100-1 Series AcroMat mats are made from 100% nitrile which doesn't compress or flatten, ever. With a medium-soft durometer rating, employees now have uninterrupted support reducing pain and discomfort by as much as 50%.

Durability and Cost Savings

TruStile Doors manufactures custom doors. If you can imagine it, they can design and build it. However, the environment is harsh and filled with:

- Sawdust and woodchips

- Metal shavings

- Fiberglass

- Finishes

- Glues

Andy and the TruStile team tried modular tiles to withstand the presence of these products, but they didn't hold up. They tried cutting rolls of mat, but this led to injury. They tried PVC foam blends for ergonomic comfort, but the mats were going flat in 6 months.

The 100% nitrile AcroMat uses lasts 5+ years with no fear of buckling, curling or flattening because it’s impervious to liquids and chemicals. As part of the AcroMat Lifetime Performance Warranty, the mats are guaranteed to never sink, flatten, lose their ergonomic cushion, or curl along the borders.

Still skeptical, understandably, Andy and his team connected with their partnering brand, Marvin Windows, which also uses the AcroMat 100-1 Series mats. They shared that their mats were still in use and intact after 5+ years. After hearing this and conducting their own trial with a free sample mat, TruStile Doors confidently moved forward with AcroMat.

According to Andy, the cost to replace all of the hazard mats with custom AcroMat mats was less than the cost of the single injury.

From eliminating mat-related slip, trip and fall hazards to indefinite ergonomic support, and from improved durability to cost savings from not having to buy mats every 6 months, the new mats have been a “win” not just for employees but the company as a whole.

These mats are like standing on a cloud. They never go flat, they're soft but strong, and they stay completely in place.

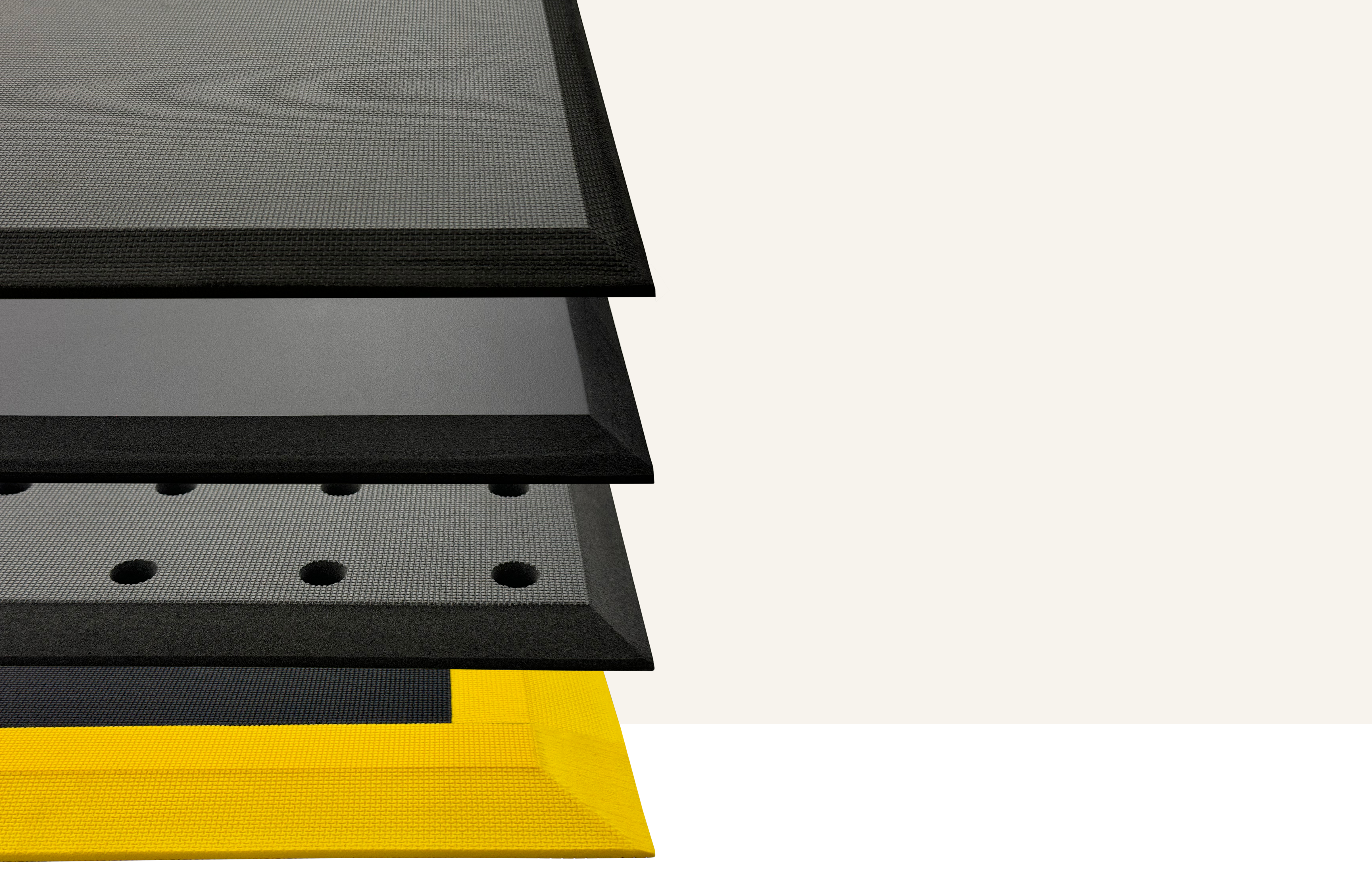

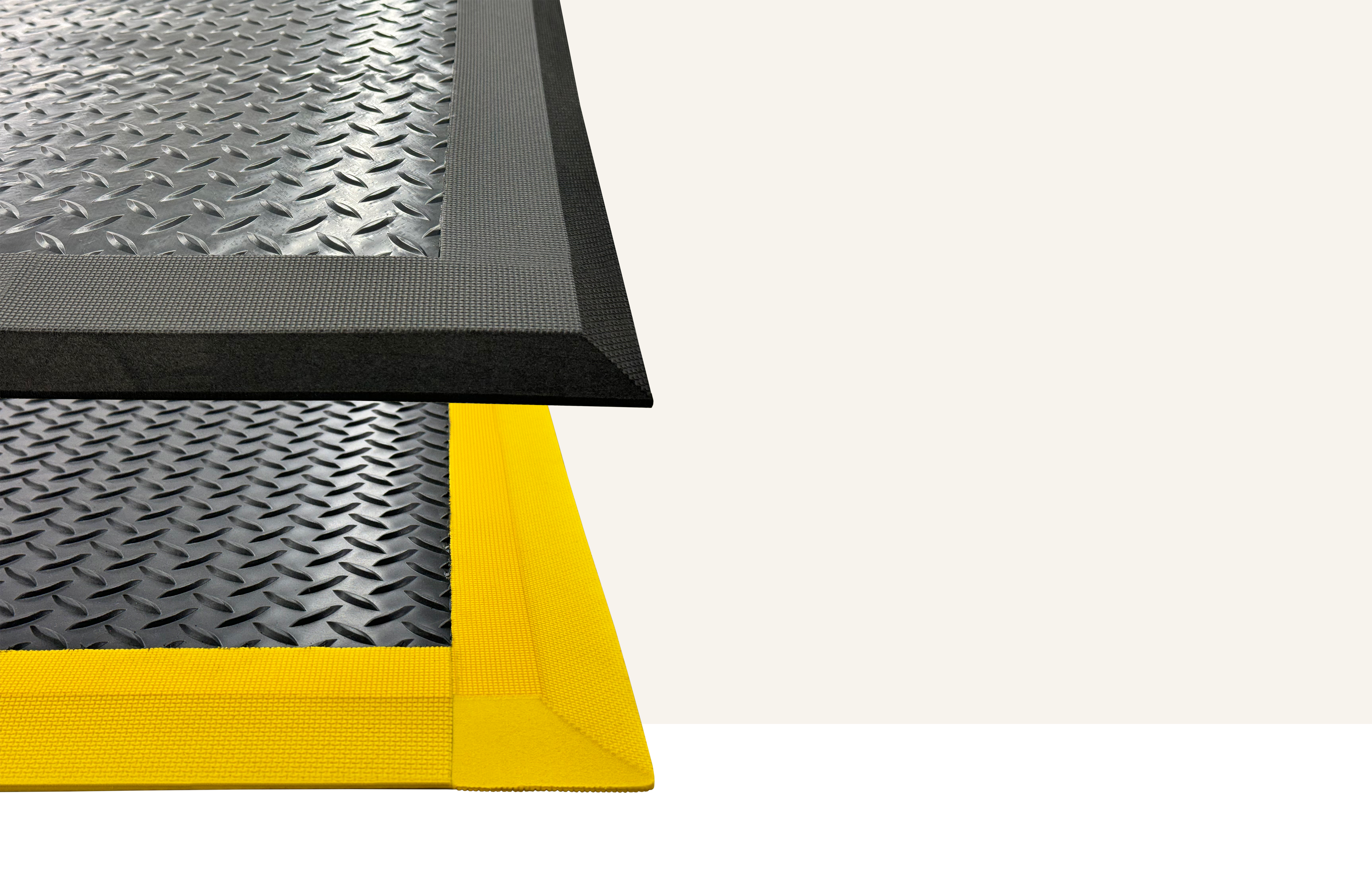

Featured Products

SOLUTIONS BUILT FOR YOUR ENVIRONMENT

100-1 Series

LEARN MORE

NutriTuf Diamond Series

LEARN MORE