40% of safety leaders say their No. 1 challenge with anti-fatigue mats is having to “piece together rectangular mats” to cover a complex layout. Piecing mats together leads to stacked and overlapped mats, inconsistent surfaces and borders, exposed cement, and countless other safety hazards.

At AcroMat, we manufacture custom anti-fatigue mats to any shape, size, angles, cutouts, and features to eliminate these challenges. But what should “custom” look like in your facility? What type of customization does your team need?

Here are the 5 most common custom anti-fatigue mat designs we hand-craft at AcroMat, including the safety and ergonomic challenges they solve.

Results from May 2023 AcroMat survey of 75 safety managers, manufacturing engineers, and continuous improvement specialists.

1. Outward-facing Cutouts or Peninsulas

Designing anti-fatigue mats with outward-facing cutouts or peninsulas is one way to eliminate the challenge of stacking or piecing together rectangular mats. Consider the following two examples.

This 550 sq. ft. one-piece custom mat includes a peninsula to ensure the operator never has to step off the pure nitrile mat during his shift – protecting his feet, joints, back, and neck:

Custom 100-1 Series mat with outward-facing cutout to help make sure operators never have to step off the mat during their shifts.

This peninsula is part of a custom mat for nVent, covering an outlet that previously required workers to step on/off their mats often. The one-piece custom shape covers the entire layout with ergonomic support; an area that was previously filled with disconnected mat pieces:

nVent

2. Lift Table Mats with Custom Cutouts

One-piece anti-fatigue mats with custom cutouts in the middle eliminate the need to try and piece together 4-5 rectangular mats to cover a workspace. This creates a consistent surface and borders all the way around the mat, reduces trip hazards, and prevents the need to purchase 4+ individuals mats (cost savings).

This custom anti-fatigue mat for Winnebago shows a rectangular shape with a precise cutout in the middle for the lift table, as well as 20-degree, ADA compliant yellow borders all the way around. Made from pure nitrile, the mat provides critical ergonomic support for up to 8 years:

Winnebago

One-piece mats with circular cutouts are an option too, as highlighted with this custom anti-fatigue mat for Medtronic. In addition to the shape, borders and circular cutout, Medtronic also added drainage holes:

Medtronic

3. L-shaped Mats

If you have an L-shaped workspace, or any other unique layout, and didn’t know custom was possible, the natural conclusion might be to piece multiple rectangular mats together to create the L-shape.

This creates preventable trip hazards and makes the mats more prone to sliding because they can’t grip the floor as intended.

Simple L-shape design, Winnebago.

Simple L-shape design, Winnebago.

Simple L-shape design with cutouts for table legs, allowing mat to slide slightly underneath the table; workers don’t have to stand on edge of mat which would create postural instability. Winnebago.

Simple L-shape design with cutouts for table legs, allowing mat to slide slightly underneath the table; workers don’t have to stand on edge of mat which would create postural instability. Winnebago.

45-degree L-shape design. Operators don’t have to take sharp angle around turn, reducing trip hazards from constant on/off stepping.

45-degree L-shape design. Operators don’t have to take sharp angle around turn, reducing trip hazards from constant on/off stepping.

Related: Winnebago Saves $150,000 with Custom Anti-Fatigue Mats

4. Built-in Cable Covers

Traditional cable covers are an undeniable trip hazard. The PVC or metal raises up to 3 inches off the ground – making them difficult to walk over, impossible to roll carts over, and requiring workers to constantly look down at their feet.

No cable cover, trip hazard from exposed cords and cables.

No cable cover, trip hazard from exposed cords and cables.

Traditional cable cover, trip hazard from PVC/metal raised several inches off ground.

Traditional cable cover, trip hazard from PVC/metal raised several inches off ground.

Built-in cable cover, lays as flat as the surface of the mat.

Built-in cable cover, lays as flat as the surface of the mat.

Built-in cable covers maintain the flat, even surface of the mat, protect cords and cables without creating trip hazards, and support cart traffic without interruption.

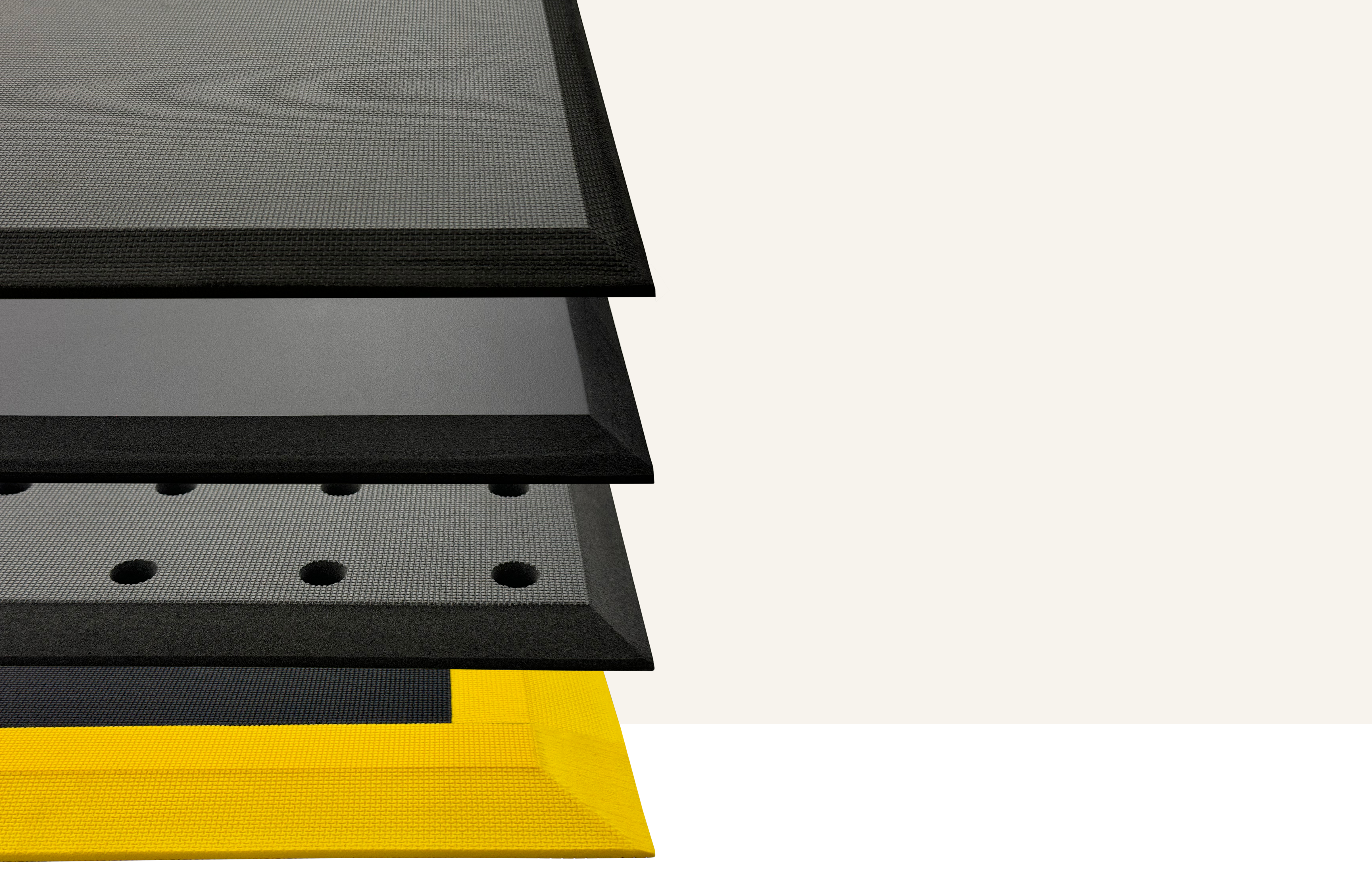

5. Yellow Borders for Entry/Exit Points

Twenty-degree, pure nitrile, ADA-compliant yellow borders clearly highlight entry/exit points in areas that need extra support. They can be added exactly where you need them with AcroSketch, and avoided where they’re not.

Cut and bonded into the mat, these yellow “super bevels” are guaranteed to never curl. Molded yellow, they are also guaranteed not to fade if kept clean.

Yellow borders added all the way around a mat. Global tractor manufacturer.

Yellow borders added all the way around a mat. Global tractor manufacturer.

Yellow borders added only where needed on 100-Cleanroom Series mat, which is Class 5 Cleanroom Certified. Medtronic.

Yellow borders added only where needed on 100-Cleanroom Series mat, which is Class 5 Cleanroom Certified. Medtronic.

Safety Isn't One-Size-Fits-All

Slips, trips, and falls remain the No. 1 cause of injury in manufacturing. Eliminating these challenges isn't one-size-fits-all. Your anti-fatigue mats shouldn't have to be either.

Don't settle for anything less than what you need to send your people home from work as safe and healthy as when they arrived.