Nearly 70% of safety leaders say their anti-fatigue mats are deteriorating years before the expected life expectancy, leading to unnecessary costs and compromising employee safety. With the right planning and maintenance, you can add over a year of life to your mats.

Here are 5 ways to extend the life of your anti-fatigue mats – simple steps you can take to protect your people and your budget.

1. Clean Your Mats Regularly

Keeping your anti-fatigue mats clean eliminates the possibility of slip, trip and fall hazards – the No. 1 cause of workplace injury – being concealed by dirt and grime. However, cleanliness isn’t just about appearance; it directly impacts anti-fatigue mat life expectancy.

The most common questions we receive are, “How should we clean our mats?” and “Can we clean our mats?” The answer is yes, depending on the fabric. Pure nitrile rubber mats – like the AcroMat 100-1, 100-ESD and 100-Cleanroom Series – are chemical resistant and liquid proof. They don’t break down to any chemical or type of scrubbing, mopping or pressure washing. Rather, cleaning strengthens nitrile.

The answer of how to clean is simply to find the cleaner and cleaning material that works best for you. Products you can confidently use to clean 100% nitrile mats:

- Ammonia

- Bleach

- Detergent

- Degreaser

- Disinfectants

- Any industrial strength cleaner

- Warm, soapy water

- Microfiber mop

- Microfiber rag

- Deck brush

- Hose

- Pressure wash

- Vacuum

An AcroMat client was ready to spend thousands on new mats, certain they needed to be replaced because they were faded. We visited the facility and saw they were in prime condition – they just hadn’t been cleaned in 6 months.

An AcroMat client was ready to spend thousands on new mats, certain they needed to be replaced because they were faded. We visited the facility and saw they were in prime condition – they just hadn’t been cleaned in 6 months.

Before taking any action with mats made of something other than nitrile, ask your suppliers for the recommended cleaning procedures. Low-quality products like PVC and even PVC/nitrile blends can break down, erode, and fade from various products and cleanings.

Key Benefit

Regular cleanings can add more than 1 year of life expectancy to 100% nitrile mats. The key is consistency.

Pro Tip

Use microfiber mops and rags whenever possible. Microfiber materials will make sure no lint or materials are left behind on the mat.

Nearly 70% of safety leaders say their mats don't last the expected lifespan. Yet, half say they don't have a cleaning cadence. Even if its quarterly, mark your calendar and stay consistent.

Nearly 70% of safety leaders say their mats don't last the expected lifespan. Yet, half say they don't have a cleaning cadence. Even if its quarterly, mark your calendar and stay consistent.

2. Repair Your Mats Early

Divots, rips and tears happen. Work layouts change. You shouldn’t have to spend the money to buy brand-new anti-fatigue mats any time an accident happens, or any time you have to move equipment around and need mats to fit differently.

Anti-fatigue mat repair is a secret most suppliers don't want you to know about. The truth is, premium quality mats – especially highly durable and versatile nitrile – can be repaired, restored and extended without disruption.

The photo below shows a good example. A manufacturing facility had a layout change 18 months after designing a custom mat. Suddenly 35 sq. ft. workspace was uncovered – forcing workers to stand on cement flooring and increasing tripping risks as workers constantly transitioned on/off the mat.

We partnered with the safety manager to re-work the mat by adding on to it. We measured the area and identified the dimensions needed. The facility shipped the mat back to our production facility. We hand-made the extension and shipped it back within 10 days.

Instead of buying a brand-new mat of more than 80 sq. ft., we added 35 sq. ft. of material to this custom mat – including 20-degree, ADA compliant yellow borders.

Instead of buying a brand-new mat of more than 80 sq. ft., we added 35 sq. ft. of material to this custom mat – including 20-degree, ADA compliant yellow borders.

Repair and extension works by taking the nitrile material we have on-site, custom cutting the right shape and size and features, then bonding the mat together with the same adhesive we use to manufacture the mats during building. The adhesive is guaranteed never to come apart.

If you don’t need a sizable extension and simply have a small rip or divot, you can use the AcroMat Repair Kit to cut the damaged piece out. We’ll send the right size replacement piece, so you can bond the section back in without any interruption. The entire process takes less than an hour.

Key Benefit

Repair and extension can save you thousands of dollars. Rather than buying new, you can simply restore or add on to your mat.

Pro Tip

Before your next anti-fatigue mat purchase, ask your mat supplier if repair is an option. And check the warranty to see what’s covered before making a purchase. Make sure the warranty language isn’t filled with confusing jargon or easy outs.

3. Inspect Your Mats Often

Regular mat inspections are like preventative health check-ups for your facility. They help you identify problem areas before they arise. Fifty-five percent of our audience says they don’t have a formal anti-fatigue mat inspection process. Another 21% says they are unsure.

This combined with 68% of safety leaders saying their mats don’t last the expected lifespan spotlights a huge opportunity. Beyond the safety benefits, regular mat inspections, early repair and even cleaning collectively give you the information you need to act strategically rather than reactively. Reactive decision making usually results in the wrong mats, the wrong shape and size, and money being spent where it doesn't need to be.

Survey results include safety managers, EHS specialists, and manufacturing engineers.

Survey results include safety managers, EHS specialists, and manufacturing engineers.

Key Benefit

Allows you to act strategically, not reactively. Consistent inspection is also a simple way to show employees the value you place on their health and safety.

Pro Tip

A tip we received from a client was to dedicate an operator to walk the floor once a month and make note of any trip, slip, fall or ergonomic hazards that are clear to the eye. This was part of the company’s “stretch goals,” and created as an opportunity to increase collaboration. They also rotate employees every few months to give all team members the opportunity.

4. Develop a Budget

Having a budget means you’re in control – not the supplier you’re partnering with. You know what you can spend, and the plan forward is built around that. Yet, 55% of our audience says they don't have a budget for anti-fatigue matting, and another 29% says they are unsure.

Without a budget and proactive approach, you lose control with the supplier and, if an injury occurs or your mats get damaged and you have to act quickly, frantic product searches often ensue – leading to the wrong mats and over-spending.

An AcroMat client in semiconductor manufacturing had a large need but a very specific budget of just $900 per month. Their need was several thousand dollars. With a set budget, they were able to communicate what they could afford, and we were able to work together to develop the plan forward – incrementally designing mats to fit their unique layouts.

Custom 100-1 Series mat designed with AcroSketch for a semiconductor manufacturer.

Custom 100-1 Series mat designed with AcroSketch for a semiconductor manufacturer.

5. Standardize Your Mat Approach

All of the above leads to our last step, which is to create a standard for anti-fatigue matting. Just 13% of our audience says they have a standard in place for anti-fatigue matting. Yet, nearly 80% say they have a standard for other safety equipment like safety glasses and PPE.

The gap between those who have a standard for safety products and those who don't for anti-fatigue mats highlights a tremendous opportunity to reduce costs and improve safety.

The gap between those who have a standard for safety products and those who don't for anti-fatigue mats highlights a tremendous opportunity to reduce costs and improve safety.

What is standardization?

Standardization means uniting your anti-fatigue mat approach across a facility. It's an approach that ensures you have the right mats (and materials) in the right areas, which naturally extends how long they last. Standardization works regardless of your vendor, supplier or manufacturer.

How do you standardize?

5 simple steps:

1. Conduct a facility assessment

2. Identify the specific types of mats and features you need

3. Bring it all together in a Standard Work Instruction

4. Communicate the SWI to every department

5. Keep gathering feedback

Need a hand? Book a virtual meeting (or free site visit) with our team to walk through the process in detail. It's our pleasure regardless if you currently partner with AcroMat or not.

Why is standardizing important?

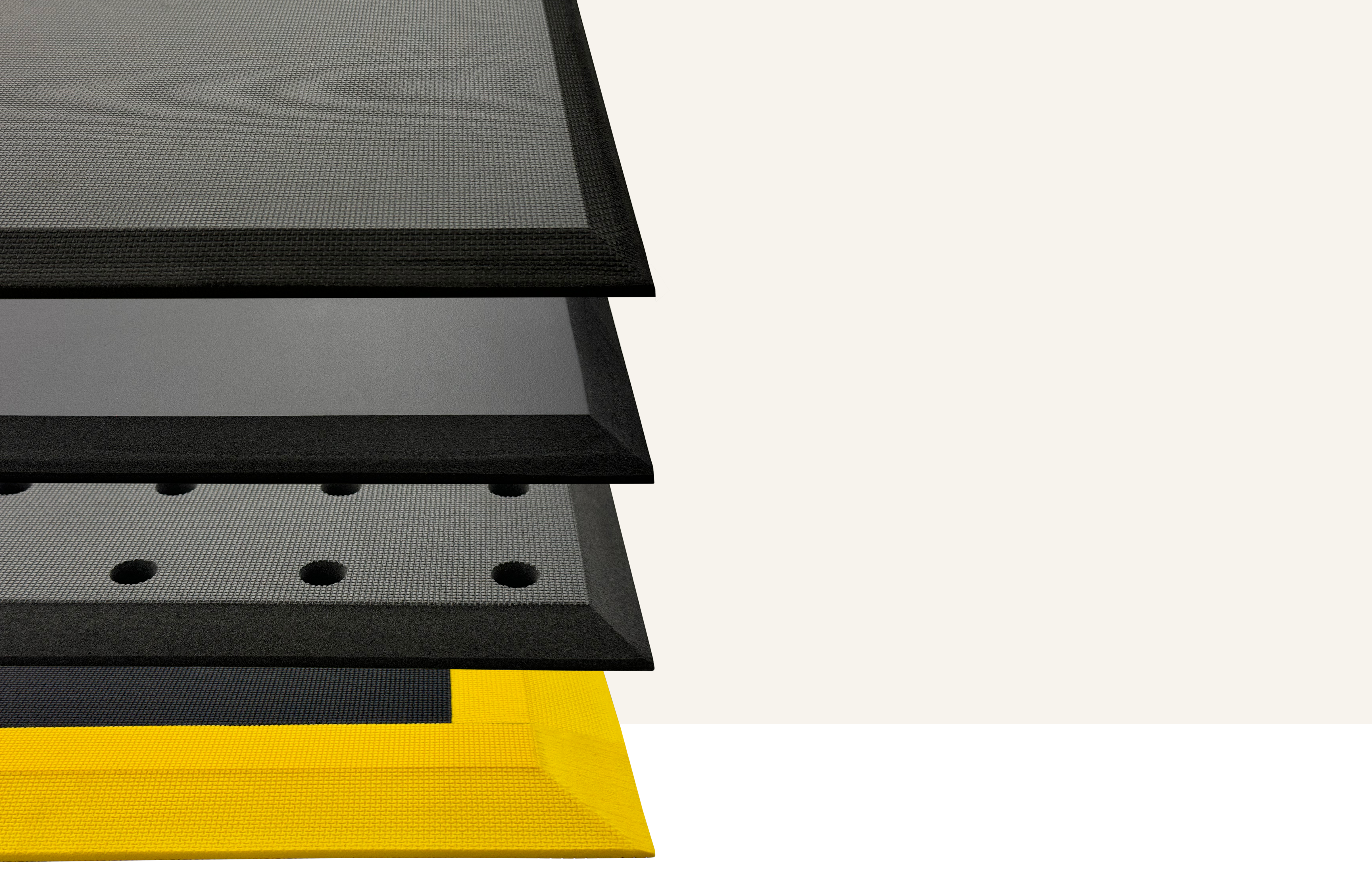

Standardizing is one of the 5S Principles of Lean Manufacturing. As a more direct example, we visited a facility this month that had 12+ different mat types, styles, and brands in use before they standardized (video below for visuals).

Different thicknesses, different surfaces, different border angles, different lifespans, exposed cement in between mats, rectangular mats stacked together to try and cover a complex layout, and durability issues:

- Trip hazards

- Slip hazards

- Ergonomic challenges

- Productivity barriers

- Unplanned and reactionary spending

This facility had many people involved in the buying and research process. Without a standard in place, the facility was filled with random, inconsistent mats.

With a standard, the entire facility now knows what type of mat each area needs, what features are required (e.g., yellow borders on every access point), and exactly where and how to get the mats needed.

They went from 12+ mats in use down to 2. New employees are educated on the standard. If someone leaves, safety remains consistent:

- No confusion

- No time-consuming Internet searches

- No reactionary buying

- Improved safety, health, and morale

How a manufacturing facility went from 12+ mats to 2, improving safety and cost savings.

Key Benefit

Standardizing unifies your anti-fatigue mat strategy and creates consistent, proactive safety approach. No safety gaps if there is turnover or change.

Pro Tip

Create a standard for anti-fatigue matting, and add it to your standard for other safety products. It takes a few hours to standardize, but the benefits are for years.

Summary

Anti-fatigue mats are an investment. Like any investment, it's important you get a measurable ROI. Getting the right mats in place and taking proactive care of them can save you in countless ways.

At AcroMat, we offer completely free site visits, safety assessments, and custom mat measurements and designs. Need a hand with any of the 5 steps above? Unsure where to begin with your anti-fatigue mat strategy? Let’s connect and make sure your people are going home from work as healthy as when they arrived.