More than 20% of safety leaders say their No. 1 complaint with anti-fatigue mats is the lack of ergonomic support. Another 25% say durability is a critical issue.

As efforts to decrease MSD injuries increase – affecting over 25% of the world’s population – you need to be sure your anti-fatigue mats are holding up. Below, we spotlight 5 ways to test the ergonomic support of your anti-fatigue mats.

1. Eye Test

One of the quickest and most effective ways to evaluate the ergonomic support of your anti-fatigue mats is through the eye test. Meaning, if it looks cooked, it likely is.

Start by watching employees as they work on the mat(s).

Does the mat maintain its shape and resilience?

Next, stand on the mat yourself.

How does it feel to you personally?

Lastly, compare the current thickness of the mat to its original thickness when purchased. Any decrease in thickness indicates a loss of critical support.

Coupled with the steps below, you can learn a lot about the ergonomic support of your mats through the eye test.

Coupled with the steps below, you can learn a lot about the ergonomic support of your mats through the eye test.

2. Review Mat Life Expectancy

Every anti-fatigue mat you've purchased has a life expectancy. As you assess your mats, refer back to the expected lifespan. If it's expected to last 6-12 months, 10 months have passed and you notice it looks flat, the support is likely gone.

Generally:

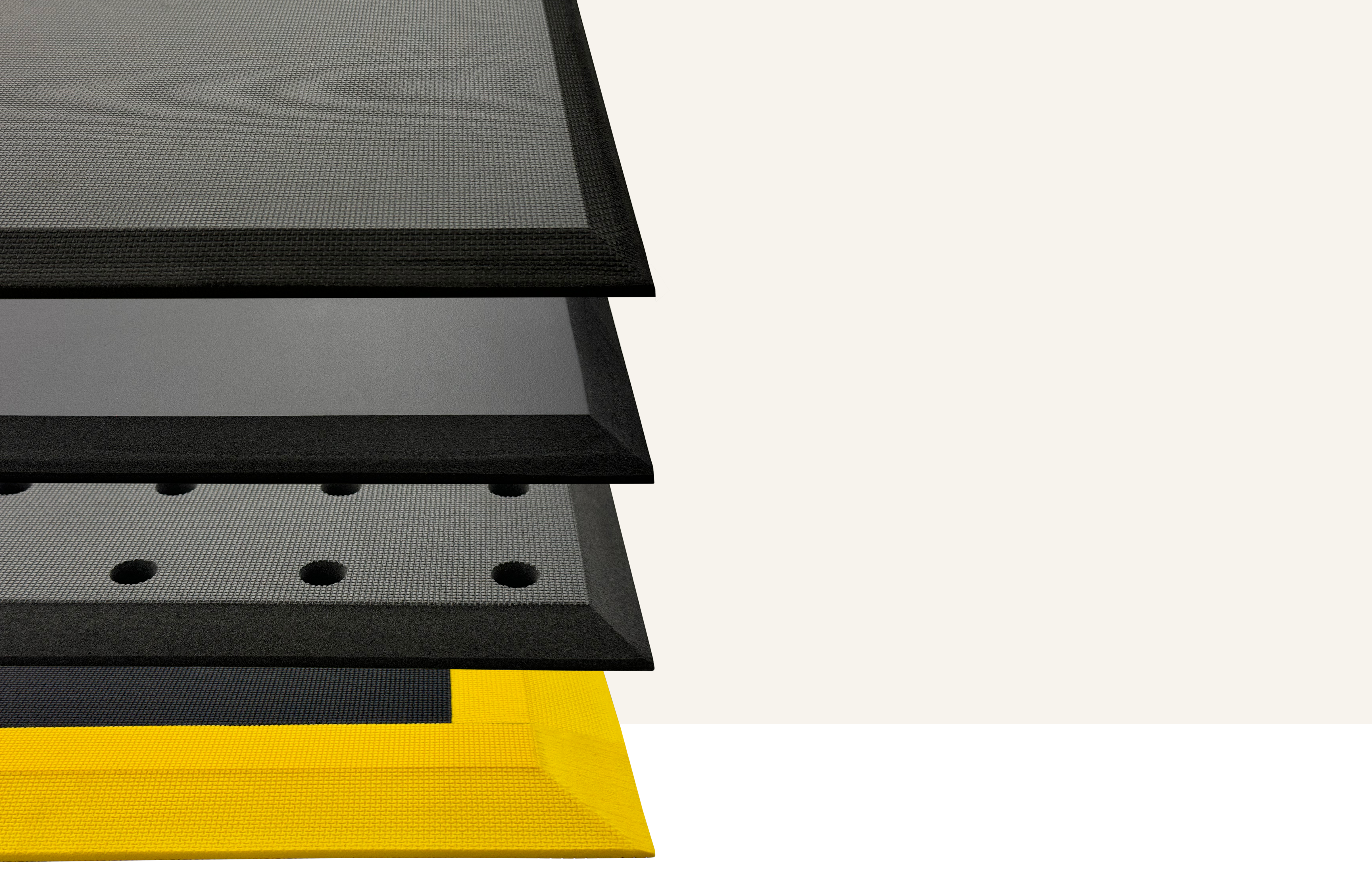

PVC foam: 6-12 months

PVC foam/nitrile blend: 1-2 years

100% nitrile rubber foam: 3-8 years

PVC: Cheapest option, not impervious to liquids, flattens

PVC/nitrile: Good comfort, chemical-resistant for a time

100% nitrile: Impervious to liquids / chemicals, never flattens

A note about 100% nitrile – which we use at AcroMat to make our 100-Series mats – nitrile does not lose its ergonomic support. How the mats age depends on the environment, whether it's kept clean, the chemicals and product it’s exposed to, and how heavily it's used. But in terms of the ergonomic support? Nitrile doesn't compress, ever.

Elasticity is how mats absorb impact and return energy to the foot. Resilient mats reduce pain and fatigue. Mats that lack resilience increase MSD injury risks. In the video above, we tested 100% nitrile vs. PVC foam. Notice how 100% nitrile rebounds immediately, while PVC lacks ergonomic resilience.

In addition to checking lift expectancy, review the warranty. Every premium mat should have a clear and concise warranty that covers ergonomic support. You should know with certainty what you're being protected against.

- Your mats will never curl

- Your mats will never compress or flatten

- Your mats will never come apart at the seams

This the AcroMat 2-year full replacement warranty in full. Many warranties give suppliers the ability to say "sorry, not our problem" as soon as you unbox a mat. If this is the case, of if it's unclear, it might be time to look elsewhere.

After reviewing expected lifespan, check the warranty on your anti-fatigue mats. Warranties should, without question, cover any losses in ergonomic support.

After reviewing expected lifespan, check the warranty on your anti-fatigue mats. Warranties should, without question, cover any losses in ergonomic support.

3. Talk to Your People

Every day we're asked about anti-fatigue mat inspection, how to assess ergonomic support, measuring firmness with durometers, and how this mat compares to that mat.

There IS a science to it all. But it can also be really simple.

When we visit client sites for safety assessments and custom mat measurements, we always start in the same place: We ask the people who use the mats every day.

- What would you change about the mat you're working on?

- How do you feel when you go home at night?

- Do you feel safe and physically supported?

- Do you have any pains you can't connect to an impact injury?

No matter how wonderfully manicured website reviews are, how good the marketing is, or shiny the sales pitch comes across, all that matters is how the mats serve your people.

Go down to the plant level. Stand on the mats yourself. Watch the operators over ~30 minutes to see how the mats holds up as they use it. And ask them for feedback.

Every ergonomic "test" should include gathering feedback from the people who use your mats every day. This custom mat was designed for Renewal by Andersen after feedback about mats being too small to cover hard surfaces in the working area.

Every ergonomic "test" should include gathering feedback from the people who use your mats every day. This custom mat was designed for Renewal by Andersen after feedback about mats being too small to cover hard surfaces in the working area.

4. Check for Stacked Mats

50% of the safety leaders we surveyed say they notice mats being "double-stacked" in their facilities. Employees stack mats for one reason: They're looking for more comfort.

We talked to Mary Plehal, Certified Ergonomist and Occupational Therapist, who shared the safety and health hazard this creates:

"Stacked mats may seem to have more cushion ... In reality, it creates postural instability and causes the feet, ankles and upwards to the lower back to have to make micro-adjustments – similar to working in high heels day after day. This leads to discomfort, fatigue, and MSD or ergonomic injuries over time."

Beyond the ergonomic hazards, stacked mats are often different sizes and even different products, which creates uneven standing surfaces. This is awkward and exposes employees to hazards such as falls and rolled ankles. Further, the height of stacked mats is often too high, creating an awkward step-off – again exposing employees to other slip, trip, and fall hazards.

50% of the 100+ safety leaders we surveyed said they've noticed mats being stacked in their facilities. Beyond the ergonomic issues, this is often a sign of employees who don't feel their health is valued.

50% of the 100+ safety leaders we surveyed said they've noticed mats being stacked in their facilities. Beyond the ergonomic issues, this is often a sign of employees who don't feel their health is valued.

5. Look for Mats Being Flipped Upside Down

Similar to the stacking of mats, employees flip their mats upside down for two reasons. Either the top of the mat is damaged, and they want a "fresh" side, like a pillow, or the ergonomic comfort is gone, and they think bottom might offer better cushioning.

Regardless of reason, both create trip hazards and are often a sign workers are frustrated with the state of their work environment. If you’re finding mats being flipped upside down or stacked, start with No. 3 above – talk to your people. Productivity, morale, and turnover may be at stake.

28% of safety leaders said they don't trigger a new mat search unless a "complaint" is received. This is reactive, and complaints aren't always verbal. Proactive inspection can spotlight issues that need to be addressed.

28% of safety leaders said they don't trigger a new mat search unless a "complaint" is received. This is reactive, and complaints aren't always verbal. Proactive inspection can spotlight issues that need to be addressed.

Summary: Take Action

- MSDs affect 25% of the world's population (National Safety Council).

- MSDs are the leading contributor to disability worldwide (WHO).

- MSDs are the most frequently reported cause of absenteeism (OSHA).

- MSDS and work environment are directly connected (NIOSH).

MSDs aren't a fad. They're here to stay. Whether the eye test, rooting out stacked mats or another testing method, make time to proactively evaluate the ergonomic support of your anti-fatigue mats. The impact is far reaching.

--

Put an AcroMat sample to the test: Request a FREE Sample Mat