Anti-fatigue mats that slide around are a slip hazard, force operators to constantly watch their steps rather than focus on the work, and reduce productivity in high-demand environments. How you can you prevent it from happening?

Here are 6 ways to stop your anti-fatigue mats from sliding:

1. Use a non-slip backing

One of the easiest and least expensive ways to keep your mats from sliding is to add a non-slip coating to the bottom surface of your mat.

At AcroMat, we manufacture non-slip coating called Grip-R which can be added to the bottom of any mat and creates a higher coefficient friction for especially slick floors. Grip-R is eco-bio friendly, waterproof, leaves no residue on the floor, and can be re-applied as needed. Grip-R can be applied to any mat order with AcroMat, or you can buy by the jar.

In less than 2 minutes, watch how Grip-R Non-Slip Coating, an AcroMat product, is easily applied and keeps your anti-fatigue mats from sliding.

"We've had our mats down for 18 months in a 24/7 manufacturing facility, and they haven't budged an inch." Amanda Eskew, CSP, EHS Specialist with Nokian Tyres, shares how her team eliminated sliding mats with custom AcroMat mats and the non-slip backing Grip-R.

Industrial tapes, such as Mighty Line Safety Floor Tape, can also help keep mats in place if properly applied and monitored. However, watch out for lower-quality tapes which will peel, potentially creating trip hazards in fast-moving areas.

2. Consider the mat materials

Anti-fatigue mats made from gels, PVC foam and nitrile-PVC blends are more likely to slide because they aren't designed not to slide.

The materials aren't impervious to liquids and chemicals, which make them more prone to buckling, curling, and eroding over time. As the bottom surfaces buckle and break down, it can lift the edges of the mat off the ground – reducing their grip on the floor and making them likely to slide. This is especially common in environments with oils, chemicals and particles that build up under your mats.

At AcroMat, we make our 100-Series mats from 100% nitrile closed cell rubber foam. Pure nitrile aids in adhering mats to the floor because it's impervious to liquids and chemical-resistant; it's literally incapable of absorbing either. This combined with a textured bottom surface and our ability to customize help keep the mats in place.

Before: Diamond-plate mat pieces strewn throughout a workstation. The PVC foam material and haphazard approach created slide-related slip and fall risks. Right: One-piece custom AcroMat designed to fit, made from 100% nitrile.

3. Stop piecing disconnected mats together

40% of the safety and production leaders we polled say "having to piece together rectangular mats to cover a complex work area" is their No. 1 anti-fatigue mat challenge, specifically the slip and trip hazards this causes.

Piecing together disconnected mats leaves each individual piece, in effect, out on an island rather than part of a whole. This makes them prone to sliding especially on slick/smooth floors.

Faced with sliding, Woodward Inc. designed a custom AcroMat mat to precisely fit the work area above. The single mat is heavier than the previous, smaller individual pieces, helping to keep the mat in place. The glove-like fit also further secures the mat in place.

TruStile Doors replaced multiple pieced-together mats after a trip and fall injury with one-piecing custom AcroMat mats designed to fit each workstation. Read Case Study.

4. Create a glove-like fit

Doing away with smaller individual mats in favor of one-piece custom anti-fatigue mats designed to fit creates a glove-like fit, which gives the mat nowhere to slide.

When mats are designed precisely for an area, they "fit like a glove" and have nowhere to slide. Designed with AcroSketch, the custom mat on the right created a glove-like fit for Lunds & Byerlys eliminating a slide-related slip and fall hazard.

When mats are designed precisely for an area, they "fit like a glove" and have nowhere to slide. Designed with AcroSketch, the custom mat on the right created a glove-like fit for Lunds & Byerlys eliminating a slide-related slip and fall hazard.

At this lift stable, Winnebago removed 4+ pieced-together mats and inserted a custom one-piece AcroMat mat that wraps fully around the workspace. This effort across several facilities helped Winnebago reduce recordable incidents by 70%. Read case study.

At this lift stable, Winnebago removed 4+ pieced-together mats and inserted a custom one-piece AcroMat mat that wraps fully around the workspace. This effort across several facilities helped Winnebago reduce recordable incidents by 70%. Read case study.

5. Look for non-slip certified products

Independent testing and certification can help you ensure the mats you're investing in are design to stay in place and less likely to slide.

The National Floor Safety Institute (NFSI) is the leading independent testing agency for anti-fatigue product testing, certification, and standard development. They use an intricate testing system that helps manufacturers like AcroMat learn how our products actually help keep users safe from slips, trips, and falls. More importantly, the test results provide you with insight to make confident buying decisions.

NFSI's testing system provides mats with a Transitional Coefficient of Friction (TCOF) rating:

- Lower than 0.4 – Low traction / higher probability of sliding

- Between 0.4 and 0.6 – Moderate traction / average probability of sliding

- Greater than 0.6 – High traction / low probability of sliding

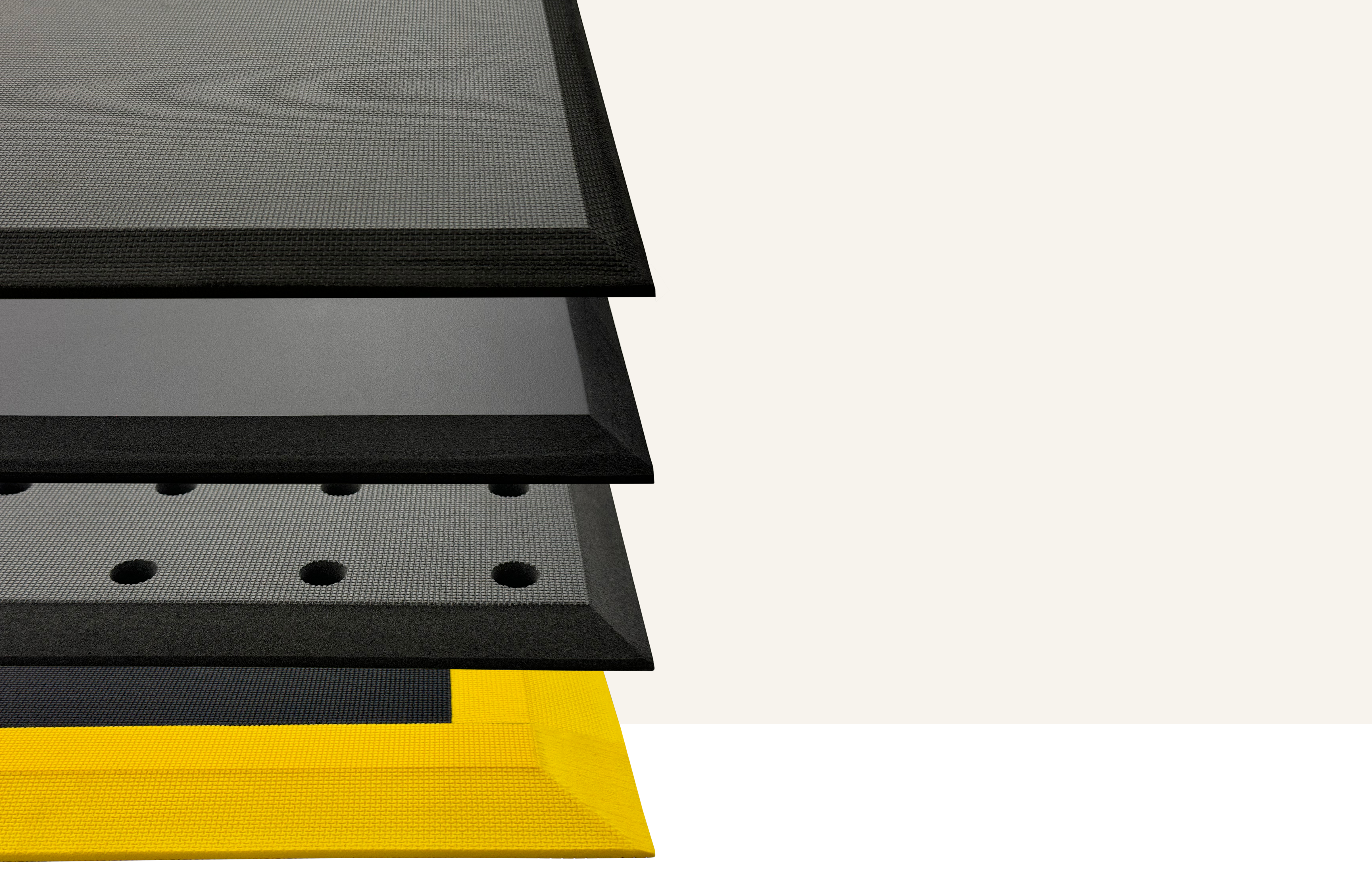

NFSI certified our 100-1 Series, 100-ESD Series, 100-Cleanroom Series, and NitriTuf Diamond Series materials as "High-Traction" thanks to its TCOF of 0.76. According to NFSI, this rating means that floor surfaces maintaining this level of slip resistance (on bottom in terms of movement, and top in terms of traction) can reduce wet-slip risks by 50%–90% — providing a safer traversal experience.

NFSI has a comprehensive public database of every anti-fatigue mat and flooring product that have earned "high traction" certification. If the ergo mats you're considering are certified, you will find them in the NFSI database.

The AcroMat 100-1, 100-ESD, 100-Cleanroom, and NitriTuf Diamond Series are all NFSI Certified for "high traction," grading at top end of the "high traction" (0.6+) category.

The AcroMat 100-1, 100-ESD, 100-Cleanroom, and NitriTuf Diamond Series are all NFSI Certified for "high traction," grading at top end of the "high traction" (0.6+) category.

Related: The Value of National Floor Safety Institute Certification

6. Keep your work areas clean

The most obvious and immediate way to limit sliding is making sure your mats and work area remain clean. Laying new mats on areas that are unclean causes them to slide (particle buildup creates a mini-wheel effect) and can lead to mold, mildew, and other bacteria if the mats aren't antimicrobial.

Sawdust, metal shavings, and fiberglass can also erode the bottom surface of your mats, further reducing the non-slip qualities and overall lifespan.

Custom shape, "glove-like fit," and 100% nitrile combine to keep this AcroMat in place. The anti-fatigue mat is cleaned twice monthly on top and underneath.

Summary

55% of safety and production leaders say they don't have have a formal anti-fatigue mat inspection process. Without strategic inspection, your facility is likely to be filled with the wrong materials, sizes and shapes – leading to issues like sliding.

Understanding what causes your mats to slide and what you can do to stop it, spend an hour this week walking through your facility and making note of needed changes. Inspection doesn't have to be complex or time-consuming; it just has to be consistent and intentional.

--

Put an AcroMat mat or Grip-R Non-Slip Coating to test: Get a free sample