What is the best anti-fatigue mat material? At AcroMat, based on two decades of customer feedback, R&D and OSHA-accredited, third-party lab testing, we believe 100% nitrile surpasses all other materials on the market. However, it's important to consider the facts before choosing a material for your environment.

Below, a deep dive into what makes 100% nitrile the best anti-fatigue mat material for industrial, food processing, cleanrooms, retail and general settings, including how it compares to PVC foam and PVC/nitrile blends.

1. A Breakdown: 100% Nitrile vs. PVC Foam

The majority of industrial-grade anti-fatigue mats are made from one of two materials: PVC foam or a blend of PVC foam and nitrile rubber. At AcroMat, we manufacture our mats from 100% nitrile rubber foam. The key difference between PVC foam, PVC/nitrile blends and 100% nitrile rubber is that 100% nitrile is molded and closed cell, while PVC foam and PVC/nitrile blends are extruded and open cell.

Open Cell vs. Closed Cell Anti-Fatigue Mats

Open cell foams, like PVC foam and PVC foam/nitrile blends, are where cells within the material have been broken during the expansion and curing process. Breaking the material allows air to enter the open spaces. This makes the material porous and permeable, meaning liquids such as oil and water will seep into the material. Open cell foams are often lighter and less dense than closed cell foams, making them feel comfortable but lacking in durability.

Conversely, closed cell foam is a highly durable rubber material comprising internal pores or cells that are "locked" into place rather than released into the air like open cell foams. The closed cell nature of the materials makes it impervious to liquids and resistant to erosion and shedding. Specific to AcroMat's closed cell 100% nitrile, it's also permanently resilient and will not lose its cushion over time from being stood on.

This is a 100% nitrile 100-1 Series AcroMat inside Nokian Tyres' manufacturing facility after 2 years of 24/7 use. The molded, closed cell material has endured for 16,000 hours of use without curling, flattening, or eroding. Watch case study video in section 3 below.

Molded. vs. Extruded Anti-Fatigue Mats

Extruding rubber (i.e., pushing material through a die) is the easiest and least expensive way to make foam mats; this is why most providers make and/or sell PVC foam mats. However, to extrude rubber, you have to add a percentage of open cell PVC foam to the overall equation. As touched on, open cell materials tend to lose their cushion, absorb liquids and bloat, as well as erode more quickly. In brief, they are designed to endure for 6-12 months.

Mat providers work hard to make their PVC foam options more durable by gluing heavy-duty surfaces over top of the PVC foam pad, like the vinyl diamond-tread often used for traditional diamond-plate mats. However, the result over time is the same.

This is an open cell PVC foam mat with diamond-tread covering inside a manufacturing facility after ~1 year. After the covering tore, the open cell material began absorbing liquids and shrinking, causing the borders to curl.

At AcroMat, our mats are molded (i.e., pressed into a mold) from closed cell, 100% nitrile rubber foam. There is no PVC foam component. The closed cell material is completely impervious to liquids. Combining 100% nitrile with our exclusive cut-and-bond mat manufacturing process allows AcroMat to guarantee (and warranty) our mats will never curl along the borders, flatten, compress, or lose their cushion.

Unlike PVC foam, which breaks down in 6-12 months, our 100% nitrile material is designed to endure without interruption for 3-8 years in even the harshest industrial 24/7 settings. In less intense environments, like distribution centers, retail counters and standing desks, the life expectancy often multiplies. While making mats from this material is more intensive on our end and subsequently a higher price for the end user, the result is an anti-fatigue mat guaranteed to perform better and last longer than any PVC foam or PVC/nitrile blended option.

Left: 100% nitrile AcroMat inside a manufacturing facility after 6 years of use. While the mat has aged and will eventually need to be replaced, the cushion and traction are intact and borders laying completely flat. Right: PVC foam mat inside the same facility after 2 years. The open cell material has severely eroded, diminishing traction and cushion.

This 2-minute video visualizes how AcroMat's molded, closed cell, 100% nitrile anti-fatigue mats are completely impervious or non-absorbent to liquids.

Summary Snapshot: 100% Nitrile vs. PVC Foam

To summarize, below is a snapshot of 7 key differences between 100% nitrile, PVC foam, and PVC/nitrile blends. AcroMat is the only anti-fatigue mat manufacturer in the industry that provides a full-replacement, lifetime performance warranty – promising our 100% nitrile mats will never curl along the borders, and never sink, flatten, or lose their cushion.

7 key differences between 100% nitrile and PVC foam/blends.

Related: AcroMat Lifetime Performance Warranty

2. What The Data Says: Reviewing OSHA-Accredited Lab Tests

Anyone can say, "This is the best anti-fatigue mat material." Claims like this should always be backed up with independent research and third-party testing. While we have seen the impact of 100% nitrile inside of our client facilities for over 20 years, we felt it important to validate our claims with testing by third-party, OSHA-accredited laboratories.

In 2025, AcroMat submitted our anti-fatigue mats to CSA Group and DDL Inc. to undergo ASTM D3574-17 Dynamic Fatigue Test by Constant Force Pounding, Curl Strength Testing After Accelerated Aging, and Seam Strength Testing After Accelerated Aging.

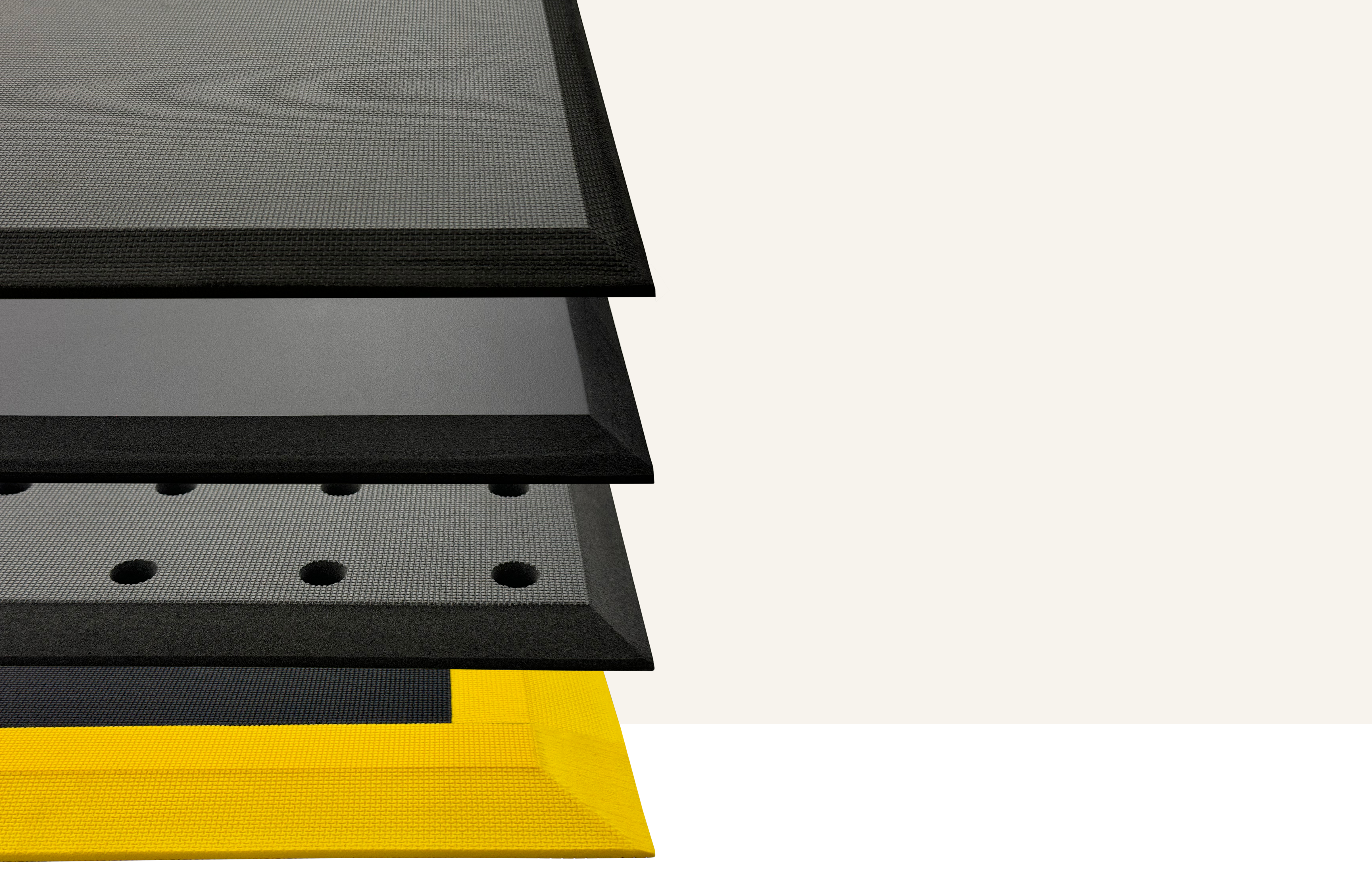

The AcroMat 100-Series anti-fatigue mats are made from molded, closed cell, 100% nitrile rubber with a thickness of 5/8 in. The material is guaranteed to never compress or lose its cushion. Border options include our standard 30-degree black borders or ADA-Compliant yellow borders; both options are guaranteed to never curl.

Test 1: ASTM D3574-17 Dynamic Fatigue Test by Constant Force Pounding

Anti-fatigue mat performance goes beyond how they feel underfoot on day one – It’s about how your mats hold up during years of constant, heavy, real-world use. To determine how well our nitrile material holds up to ongoing use, the material was subjected to ASTM International's standardized dynamic fatigue test.

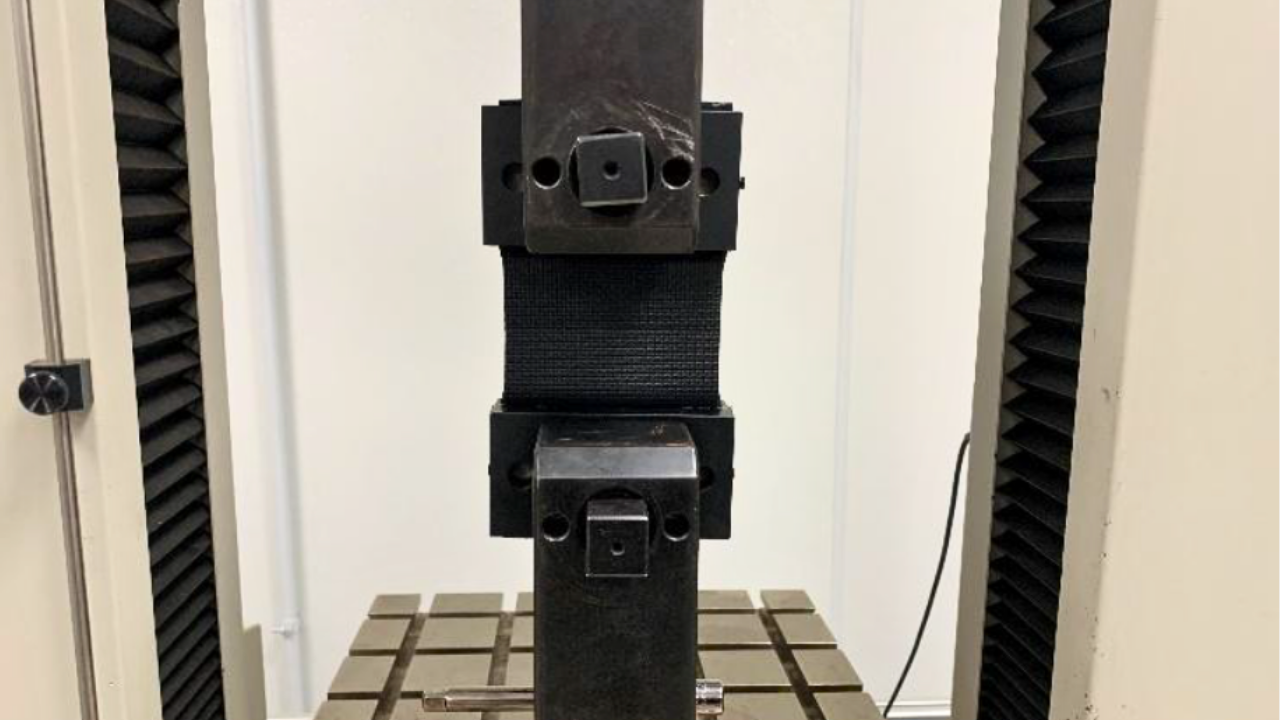

Recognized as the industry-standard method for evaluating how well a mat's cushion endures over time, the ASTM D3574-17 Dynamic Fatigue Test involves compressing a mat 80,000 times with 170 lbs. over a specified period of time. DDL Inc., an ISO/IEC 17025-accredited laboratory based in Minnesota, conducted the test and evaluated our 100% nitrile material alongside two top-selling competitor mats made from extruded PVC foam.

After 80,000 compressions, the 100% nitrile material proved to be permanently resilient – maintaining greater than 98% thickness and regaining the ~2% as the pounding wore on. The PVC foam mats lost 4.4-6.1% thickness and continued to compress over time, indicating rapid and permanent breakdown.

Photo provided by DDL: AcroMat 100-Series molded, closed cell, nitrile rubber material preparing to undergo ASTM D3574-17 Dynamic Fatigue Test by Constant Force Pounding.

Summary of DDL's Dynamic Fatigue Test results, showing loss of thickness by percentage.

The key metric in the ASTM International D3574-17 Dynamic Fatigue Testing is loss of thickness percentage. Competitor PVC Foam Mat 1 lost 6.1% of its thickness after 80,000 compressions, while Competitor PVC Foam Mat 2 lost 4.4% of its thickness after 80,000 compressions. The AcroMat 100-Series 100% nitrile material lost just 1.9% of its thickness. A thickness retention greater than 98% indicates permanent resistance to deformation, while loss greater than 2% indicates higher likelihood of permanent deformation.

More importantly, both PVC foam mats failed to regain thickness after the initial 4.4-6.1% loss, while the AcroMat nitrile material regained its original thickness after the initial 1.9% loss.

Screenshot from DDL report: Showing how AcroMat's 100% nitrile steadily regained its thickness over time, returning to its original cushion as the test wore on.

Screenshot from DDL report: Showing how Competitor PVC Foam Mat 1 failed to regain thickness between 60 minutes and 24 hours, losing additional cushion as the test wore on.

Test 2: Curl Strength Testing After Accelerated Aging

Curling anti-fatigue mat borders is a dangerous workplace safety concern. OSHA identifies slip, trip, and fall injuries as the No. 2 most common workplace injury, often linked to uneven and inconsistent flooring. When an anti-fatigue mat curls, the raised lip catches shoes, carts, and other equipment. This can result in a serious injury, missed time, lost productivity, worker’s compensation, as well as broken trust and morale.

To validate our lifetime guarantee that our borders will never curl, we had CSA Group, an OSHA Nationally Recognized Testing Laboratory (NRTL), subject our 100% nitrile anti-fatigue mats to 5 years of accelerated aging alongside one of the most commonly use diamond-plate mat designs – an extruded PVC foam mat with a vinyl diamond-plate surface and waterfall edge.

Photos provided by CSA Group: Showing the AcroMat nitrile material laying flat after 5 years of simulated stress, and PVC foam mat having curled after 1 year of simulated stress.

To simulate 5 years of aging, CSA Group placed three samples of each mat in a controlled environmental chamber at 80°C and 80% relative humidity – replicating heat, chemical, and moisture exposure. This accelerated aging process is based on the Arrhenius Equation, a standard scientific approach used to predict material longevity and time-to-fail.

At intervals representing 1, 2, 4, and 5 years of simulated aging, the mats were visually inspected for edge curling – a key indicator of degradation and dimensional instability.

The AcroMat 100% nitrile mats showed zero sign of curling after 5 years, while the traditional diamond-plate mat with PVC foam pad curled in less than 1 year. Directly from CSA Group's final report, "AcroMat Series 100-1 samples did not exhibit any edge curling at any point during the accelerated aging protocol. Competitor sample exhibited edge curling beginning at the simulated 1-year interval and continued to degrade over time."

Screenshot from CSA Group report: Showing how AcroMat's nitrile material and design process led to no curling after 5 years, while the traditional PVC foam mat with diamond-plate curled in less than 1 year.

Test 3: Seam Strength Testing After Accelerated Aging

When it comes to the longevity of your anti-fatigue mats and other safety flooring solutions like modular tiles, seams are often the first point of failure. Over time, heat, moisture, and heavy use can cause seams to weaken or separate – leading to trip hazards, shorter product life, and constant re-purchases.

At AcroMat, we warranty seam integrity to ensure confidence in the performance of our products. To further validate this guarantee, we had CSA Group subject our 100-1, 100-Cleanroom, and 100-ESD Series mats – all made from 100% nitrile – to 4 years of accelerated aging followed by high-force mechanical pull testing.

The AcroMat seams remained uncompromised after 4 years and grew stronger from year 1-4 despite constant exposure to heat, chemicals, and moisture. Specifically, the average force at break increased by 5.03% from year 1-4, while the average elongation at break reached 202% (3X) its original measurement – indicating an increase in seam strength over time.

Photos provided by CSA Group: Showing the AcroMat nitrile material before and during one of the mechanical pull tests.

Results from CSA Group report: Over 4 years of accelerated aging, the seams along the AcroMat nitrile samples not only maintained their structural integrity but increased in strength from year 1 to year 4.

Related: AcroMat Testing Data & Certifications

3. Removing ambiguity from life expectancy estimates

Anti-fatigue mat life expectancy is often confusing because it lacks clarity. If your mat maintains its cushion for 10 years but curls within 6 months, the useful life is 6 months because it's now a dangerous trip hazard. Cushion is irrelevant. Further, product pages often give you a range of years but don’t clarify whether this means 40-hour work weeks (2,080 hours of use/year) or 24/7 use (8,760 hours/year).

We define useful life as an anti-fatigue mat that is performing as promised without interruption – including no sinking, flattening, loss of cushion, curling borders, seam failures, or other issues like bloating and erosion. In addition, our life expectancy estimates assume 24/7 use as many manufacturing facilities remain open around the clock.

As you compare anti-fatigue mat materials to and try to determine expected lifespan, you can remove ambiguity with these 5 steps:

1. Get clarity on your mat provider's definition of "life expectancy"

Ask, ask, ask! What do you mean by life expectancy? How does expected life change by environment? What should we expect in our setting? When you say useful life, do you mean cushion, curling, or something different? Are your estimates based on 24/7 use or 40-hour work weeks? If you say your mats will last X years and they break down more quickly, are we protected in any way?

Two workspaces in an Uponor facility. The PVC foam mats have flattened, eroded, and curled. The 100% nitrile AcroMat has remained entirely intact and is also covered under our Lifetime Warranty – ensuring it will never sink, flatten, lose its cushion, or curl along the borders.

2. Read the warranty fine print

Every anti-fatigue mat should have a clear, unambiguous performance warranty that holds your mat provider accountable for faulty performance, and you should know with certainty what you're protected against.

At AcroMat, our Lifetime Performance Warranty states:

- Your mats will NEVER curl along the edges

- Your mats will NEVER flatten or lose their ergonomic cushion

- The bonds along your mat will NOT split, weaken or come apart

Simple, clear, no easy outs. Watch out for "lifetime limited" and "manufacturing guarantees" with no performance protections. These rarely cover anything other than promising the mat will be made correctly, and they often give mat providers an easy out.

This windows manufacturer replaced modular tiles that were constantly coming apart at the seams, including seams not covered by warranty, with one-piece, custom, 100% nitrile AcroMat mats with seams warrantied to remain intact.

3. Go straight to the technical specifications

Most product pages are filled with sneaky trademarked names, like SpongePlus2000. These types of names are often used to hide the fact that it's a simple PVC foam mat similar to everything else on the market. Find the facts and physical construction of your mats by reviewing the technical specifications before buying into promo language. If the technical specs. aren't immediately available, don't be afraid to ask for a copy.

4. Review certifications, ask for testing results, and watch case studies

As discussed above, independent testing and certifications provide critical objectivity. They also give you control during the research and buying process; you're relying on objective assessments from third parties rather than promises or promotions by the mat provider.

Ask your mat provider for any relevant certifications or test data that illustrate how their mats will perform. In addition, real-life case studies from companies in your industry can provide first-hand insight. Below, Titans of CNC and Nokian Tyres share their experiences using AcroMat's nitrile anti-fatigue mats.

Three employees with Titans of CNC discuss the durability of their 100% nitrile AcroMat mats, including the impact on their health and value of the lifetime warranty.

Nokian Tyres' EHS Specialist and three operators share their experience with AcroMat after their nitrile mats have been in place for 2 years in a 24/7 facility.

5. Conduct a rigorous trial process

This is the simplest yet most important step of the anti-fatigue mat buying process. Before making a sizable investment, ask for a free, full-sized sample mat to trial in your environment. This gives you the opportunity to validate claims, compare and contrast, get feedback from employees using the mat, and evaluate performance in your specific setting.

We recommend a trial of at least 200 working hours. This is the bare minimum amount of time needed to discern key performance indicators like comfort and durability. Further, avoid trialing mats in breakrooms and business offices. Put the mat in the environment it will be used; expose it to the harsh products and heavy use it will be met with on a day-to-day basis.

Here are 5 questions that can help you integrate honest, genuine feedback from the people who will be standing on the mats every day:

- Do you feel safe and physically supported?

- Has the mat been sliding around or curling?

- How do your feet/back/neck feel after each shift?

- How is the mat holding up to liquids and chemicals?

- How does this mat compare to what you have been using?

4. Summary: Ask. Listen. Document.

We manufacture anti-fatigue mats for some of the world’s top brands – from manufacturing facilities to cleanrooms and labs, to food processing and retail spaces. Over two decades, we have invested heavily in researching, testing, and trialing rubber compounds to uncover the right blend of comfort, durability, and traction. Based on our results, we choose to make our mats from 100% nitrile. We firmly believe it's the best anti-fatigue mat material in the world.

Glimpse of some of the customers who regularly partner with AcroMat

But there are a lot of good options out there in addition to nitrile. If you are considering a certain material, do your research, ask questions, and conduct a trial. Following a standardized process not only protects your investments, but it helps ensure your most valuable asset, your people, are satisfied and engaged.

Cintas surveyed 2,500 U.S. employees. Over 90% say they feel more cared for by employers if there are premium anti-fatigue mats in place. Over 90% also said they prefer to work for a company that provides high-quality mats.

Employees recognize when they are invested in, and they prefer to work for companies that make them feel this way. Make sure your anti-fatigue mats are doing their part.