At AcroMat, we make premium-quality anti-fatigue mats for standing workers inside of manufacturing, food processing, retail, and cleanroom environments. As of 2025, we have been serving the world's leading brands for over 20 years.

But what makes AcroMat different than every other anti-fatigue mat provider? How do our mats contribute to safer workplaces, healthier employees, and higher morale while reducing year over year spend for our customers? From quality and customization to performance guarantees, here are 6 reasons why companies choose AcroMat for their anti-fatigue mat needs.

6 Reasons Why Companies Choose AcroMat:

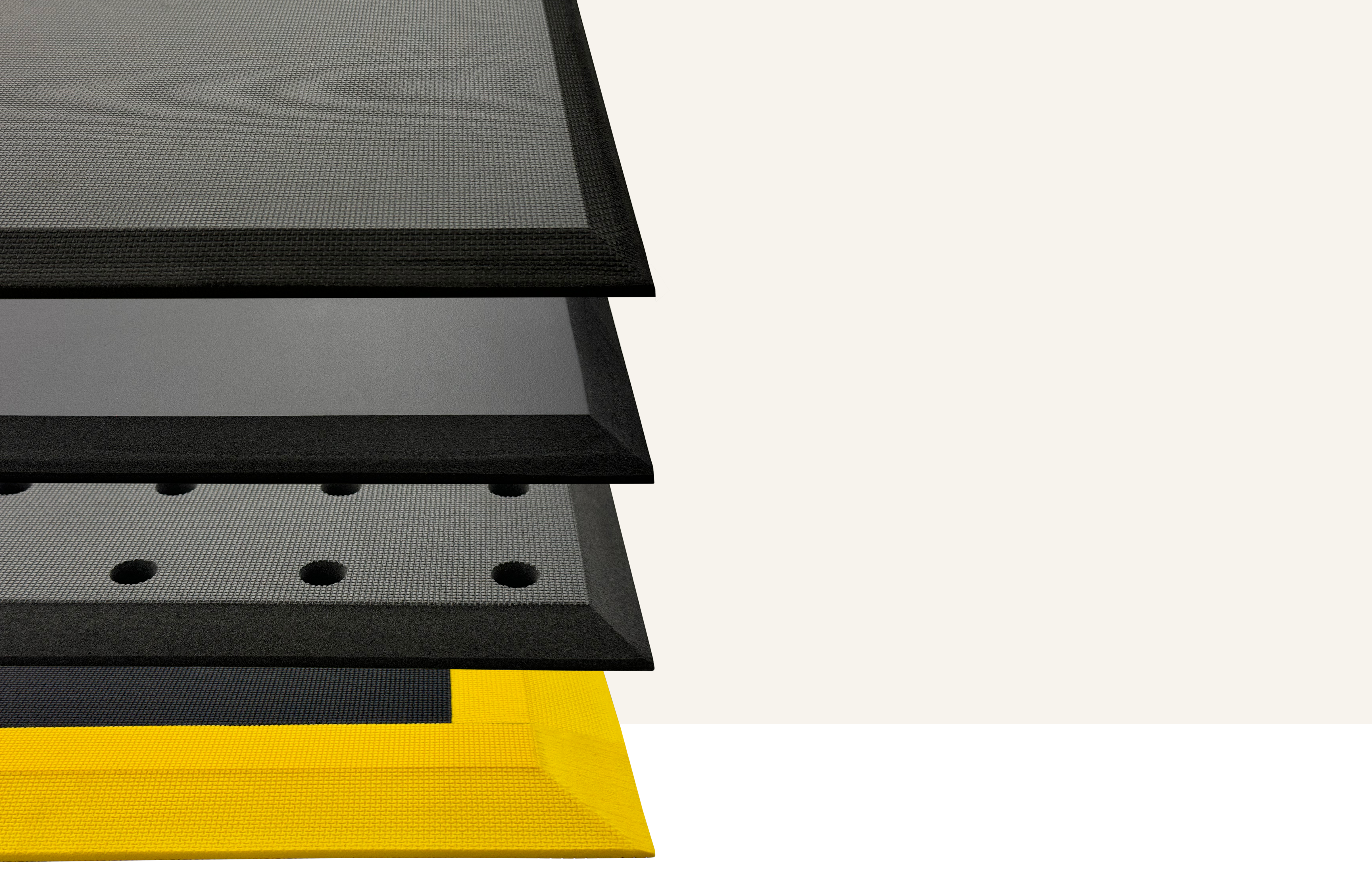

1. Superior anti-fatigue mat quality

Almost every mat on the market is extruded using PVC foam or a PVC foam blend. The key difference with AcroMat, our mats are molded (not extruded) from a virgin, closed cell, 100% nitrile rubber foam with no component of PVC foam. This translates to a much higher durability, complete imperviousness to liquids and chemicals, and our guarantee your mats will never sink, flatten, lose their cushion, or curl along the edges.

In short, PVC foam mats are designed to last for months before you need to replace them. Pure nitrile mats are engineered to last for years without failure, issue, or interruption.

Titans of CNC shares why they came to AcroMat for "the best" anti-fatigue mats on the market, including the ergonomic benefit that followed.

Molding vs. extruding

Extruding rubber (i.e., pushing material through a die) is the easiest and least expensive way to make foam mats; this is why most providers make and/or sell PVC foam mats. However, to extrude rubber, you have to add a percentage of open cell PVC foam to the overall equation. Open cell materials lose their cushion over time, absorb liquids, and erode more quickly. In brief, they are designed to endure for 6-12 months.

Mat providers work hard to make their PVC foam options more durable by gluing heavy-duty surfaces over top of the PVC foam pad, like the vinyl diamond-tread often used for traditional diamond-plate mats. However, the result over time is the same.

This is a 100% nitrile 100-1 Series AcroMat inside Nokian Tyres facility after 2 years of 24/7 use. The nitrile material has endured for 16,000 hours of use without curling, flattening, or eroding. Watch case study video in section 4 below.

At AcroMat, our mats are molded (i.e., pressed into a mold) from closed cell, 100% nitrile rubber foam. There is no PVC foam component. The closed cell material is completely impervious to liquids. Combining 100% nitrile with our exclusive cut-and-bond mat manufacturing process allows AcroMat to guarantee (and warranty) our mats will never curl along the borders, flatten, compress, or lose their cushion.

Unlike PVC foam, which breaks down in 6-12 months, our 100% nitrile material is designed to endure without interruption for 3-8 years in even the harshest industrial 24/7 settings. In less intense environments, like distribution centers, retail counters and standing desks, the life expectancy multiplies. While making mats from this material is more intensive on our end and subsequently a higher price point, the result is an anti-fatigue mat guaranteed to perform better and last longer than any PVC foam or PVC/nitrile blended option.

At minimum, you will get twice the use from an AcroMat over nearly every other foam mat.

Winnebago was replacing their previous PVC foam mats every 4 months. The Fortune 1000 replaced the box-store PVC foam mats with 300 nitrile AcroMat mats that are now lasting years, saving Winnebago $150,000 in mat expenses. Read case study.

Related: The Best Anti-Fatigue Mat Material: 100% Nitrile vs. PVC Foam

2. Custom mats designed to fit

According to OSHA, slips, trips, and falls are the No. 2 most common workplace injury. They’re also the No. 1 most preventable workplace injury. One of the main culprits is the conventional and antiquated "piecing and piling" approach to anti-fatigue mats.

When you’re limited to ridged standard-size mats, you’re stuck piecing them together to fill complex layouts. Piecing and piling leads to gaps between mats, overlapping borders, exposed harsh flooring like cement or metal grating, and inconsistent thicknesses, surfaces and traction. In other words, it can cause dangerous slip, trip, and fall hazards.

At AcroMat, we invented the solution to this problem. That is, one-piece custom anti-fatigue mats made to any shape and size to seamlessly fit your layouts. Custom anti-fatigue mats designed to fit eliminate all mat-related slip, trip and fall risks by creating a consistent surface, traction, cushion, and comfort from end to end in your workspaces.

After an employee suffered a serious ankle injury from tripping over a gap between two standard mats pieced together, TruStile Doors partnered with AcroMat to design custom mats to seamlessly fit every workspace. According to the EHS Manager, the cost of the entire custom mat project was less than this single injury. Read case study.

Our custom mat building tool, AcroSketch, the only tool of its kind, gives you the ability to design your mats to any shape and size in minutes. No snapping pieces together, no delayed quoting processes, no hidden custom fees.

3. Higher Employee Productivity

According to Harvard Business Review, 86% of employees lose at least 2 hours of productivity every day because of inefficient workplace design, and the average adult in the U.S. makes between 30,000 and 35,000 decisions a day.

Too often, your anti-fatigue mats are contributing to lost productivity by forcing employees to make even more decisions. Operators move throughout their workspaces 8-10-12 hours a day. They're constantly making decisions – from machinery and tools to hitting deadlines, productivity, safety, communication and moving around.

When you piece and pile mats to fill a work area, employees have to constantly think about:

- How to step over broken/curling borders without tripping

- How to step between multiple mats without tripping

- How to step around overlapping or stacked mats

- Where to find comfort if half on/off of their mats

- How to safely navigate around sliding mats

This approach makes decision-making more complicated, diminishing the quality and quantity of their output. Employees are forced to focus on every step just to stay safe rather than able to hone in on the work itself. Conversely, custom anti-fatigue mats designed precisely to fit improve productivity by making employee choices intuitive:

- Consistent surface

- Consistent traction

- Consistent cushion

- Glove-like fit prevents risk of sliding

- Glove-like fit prevents on/off stepping

- No gaps, trip hazards, or ergonomic injury risks

This facility previously hand-cut roll mats to fill its workspaces. What they didn’t realize, this approach made employees’ jobs more difficult and confusing, reducing productivity and impacting morale. The one-piece, seamless custom mats made employee decisions intuitive – allowing them to focus on the work instead of their steps.

With AcroMat, this facility custom-designed yellow sections into their anti-fatigue mats to improve spatial awareness using our proprietary custom builder, AcroSketch. The result is faster and intuitive decision making, leading to improved productivity.

4. Eliminating Slide-related Slip and Fall Risks

Over 20% of users are dealing with anti-fatigue mats that slide around, creating a dangerous and preventable slip, trip, and fall hazard. One way to prevent sliding anti-fatigue mats is to create a glove-like fit by custom-designing your mats to perfectly fit the layout. With no room for the mat to move around, it’s essentially anchored in place.

If custom isn’t an option or the right fit in your facility, another proven, fast and inexpensive solution is to apply a non-slip coating to the bottom of your mats. At AcroMat, we are the exclusive manufacturer of Grip-R Non-Slip Coating – an eco-bio friendly, waterproof, non-slip backing that is compliant with all OSHA regulations.

Grip-R is painted onto the bottom of your mats, dries to create a tacky feel, and creates a firm bond between floor and mat to keeps your anti-fatigue mats firmly in place. The result is the elimination of slide-related slip and fall risks without any risk or damage to all floor types.

Nokian Tyres was previously dealing with sliding mats, affecting employee morale while presenting a safety risk. In this video, EHS Specialist Amanda Eskew and three operators share how Grip-R made sure their mats “haven’t budged or slid and inch” in nearly two years.

Related: 6 Ways to Prevent Sliding Anti-Fatigue Mats

5. Personalized, Accountable and Blazing-Fast Service

AcroMat isn't an online supplier with chatbots and auto-replies or looking for a quick sale. We are a family-owned, U.S.-based anti-fatigue mat manufacturer that is passionate about keeping your employees safe, and a 20-year history serving the world's leading brands.

The world's leading brands have entrusted AcroMat with their anti-fatigue mat needs for over 20 years, from industrial to retail, cleanroom, and food manufacturing settings.

We design, precision-cut and assemble our mats directly from our production facility here in Lakeville, Minnesota, just south of the Minneapolis Metro. Our team provides over 1,000 on-site consultations and anti-fatigue mat inspections every year – including helping clients put together standardized and strategic plans. Our team is always on the other end of the line and responds to every inquiry within 24 hours, often within the hour.

As the anti-fatigue mat industry becomes more online and disconnected by forcing you to deal exclusively through web forms, delayed quote times, automated emails and sellers motivated more by the transaction than what’s best for your people, AcroMat remains committed to serving the end-user exactly where, when, and how you need support.

Above all, we work hard to back up our claims with satisfaction guarantees, moneyback guarantees, a 5-day lead-time guarantee, and a Lifetime Performance Warranty. We want to be accountable to every customer we serve and every mat we make.

Ron Bishop with Optum Inc., a Fortune 500 global brand, talks about how his team improved safety and morale by switching to AcroMat. He also shares the "unmatched" service he has experienced in partnership with AcroMat. Read case study.

6. Improved Engagement and Morale

Cintas recently surveyed over 2,500 full-time professionals in the U.S. Over 90% say they feel more cared for by employers if there are premium anti-fatigue mats in place. Over 90% also said they prefer to work for a company that provides high-quality anti-fatigue mats.

Conventional anti-fatigue mats aren’t good enough to provide the safety or morale boost you need. Box-store mats sink, flatten, compress, curl, and come apart. They come with no performance warranty protections. And they often contribute to risks rather than actively preventing them.

This custom AcroMat mat for a Fortune 500 industrial manufacturer is backed by a Lifetime Warranty that promises the mat will never curl or lose its ergonomic cushion. "Just wanted to say how well your mats do from a Lean 5S standpoint: Sort, Strengthen, Shine, Standardize and Sustain. Not only worker safety but aesthetic too," shared the EHS Manager.

AcroMat anti-fatigue mats are guaranteed to never flatten or lose their ergonomic cushion, warrantied not to curl eliminating a dangerous trip hazard, and can be designed to any shape and size to ensure a seamless fit. They are NFSI “High Traction” Certified reducing wet-slip risks by 50-90%, and the medium-soft cushion has proven to reduce pain and discomfort by up to 50% compared to hard surfaces and impact injuries by 70%.

In short, integrating AcroMat mats into your facility is about much more than "getting better mats." You’re building a workplace employees want to be part of. You’re showcasing to these valued workers your commitment to making sure their workspaces are of the highest quality, and ensuring they get home from work as safe and healthy as when they arrived.

Aaron Anderson-Walker, Senior Manufacturing Technology Engineer with 3M, shares how the Fortune 500 improved safety, elevated productivity, and boosted morale for 1,200+ employees with AcroMat anti-fatigue mats.

Bonus: Peace of Mind

All AcroMat 100-1 Series, 100-Cleanroom Series, and 100-ESD Series anti-fatigue mats are covered under a Lifetime Performance Warranty guaranteeing critical, best-in-class safety and performance protections. The Lifetime Warranty promises your 100-Series mats will never sink, flatten, lose their ergonomic cushion, or curl along the borders.

The AcroMat Lifetime Performance Warranty is designed to ensure your standing workers are protected, allow you to buy with confidence and certainty, and hold our team accountable to every mat we make on your behalf.

Unlike traditional manufacturing guarantees and lifetime limited warranties, which only assure your mats will be made without defect, this warranty guarantees the manufacturing and performance of the mat – setting an entirely new standard for warranty protections.

Ultimately, the warranty empowers you to have peace of mind for years at a time, without anxiety or fear your mats are causing safety issues, creating moral problems, or in constant need of replacing. Set them. Forget them. And get back to work.