35% of the safety and production leaders we polled throughout 2023-2024 say the No. 1 complaint they receive from employees about their anti-fatigue mats is, “They’re too small.”

When your anti-fatigue mats are too small, employees have to step on/off their mats constantly, often work on the beveled edges of the mat or half on/half off, and tend to piece mats together to try and cover their workstations. This slows productivity, increases slip, trip and fall injury risks, and can impact employee morale.

Are your mats too small?

With help from multiple ergonomists and experience from EHS leaders, here are 5 signs your anti-fatigue mats are too small.

1. Constant On/Off Stepping

"We have a problem with employees stepping on/off their anti-fatigue mats 500 times day."

This is directly from email inquiry we received in June 2024 from an EHS Manager with an aerospace manufacturer. Constant on/off stepping is something we see in nearly every facility we visit, and it’s a risk to employee health and safety.

According to Mary Plehal, Ergonomist and Owner of OptimaEHS:

“While stepping on/off might seem inconsequential, it can lead to increases in safety concerns in categories such as slips, trips and falls; cuts, punctures and scrapes; among other things. It can also contribute to ankle, knee and hip/low back fatigue if the on-off stepping occurs at high frequency – say, hundreds of times per 8-10 hour shift.”

Beyond this mat clearly having gone flat, removing any ergonomic benefit, it's also too small and forcing workers to constantly step on/off the mat, creating a clear trip hazard.

Beyond this mat clearly having gone flat, removing any ergonomic benefit, it's also too small and forcing workers to constantly step on/off the mat, creating a clear trip hazard.

2. Noticeable Edge-Standing

Pure nitrile anti-fatigue mats – what we use to make our 100-Series mats here at AcroMat, have proven to reduce pain and discomfort by as much as 50% compared to hard surfaces like concrete, hardwood and tile. However, even the best mats will increase pain and discomfort if they’re the wrong size.

Anti-fatigue mats that are too small cause noticeable edge-standing – that is, one foot on the mat while the other is half on/half off or completely off the mat.

According to Mike Janak, Ergonomist with ErgoFactor:

“Standing with only half the foot in contact with the mat promotes a non-neutral ankle posture that would be similar to standing on high heels. If the standing postures are static, and the worker stands at the edge of the mat for prolonged periods without moving his/her feet, then the non-neutral ankle posture may result in musculoskeletal injury.”

“I was in an assembly plant with a 7-station assembly line that has straight, modular snap-in modular tiles,” adds Mary. “A complaint of the employees is that when they want to stand close to the workbench, the legs of the workbench prevent the straight mats from providing coverage, so employees often stand with the balls of their feet on concrete and their heels on the bevel of the mat. From a musculoskeletal perspective, this can increase tarsal/metatarsal joint issues – where the foot bones meet the toe bones at the ball of the foot.”

Edge standing impacts the biomechanics of the ankle all the way up to the lower back and neck, increasing discomfort and MSD injury risks.

Edge standing impacts the biomechanics of the ankle all the way up to the lower back and neck, increasing discomfort and MSD injury risks.

Modular tiles, while providing good traction, are limited in terms of shape and size. As a result, operators at this medtech company are forced to stand on the beveled edges, increasing tarsal/metatarsal joint issues.

Modular tiles, while providing good traction, are limited in terms of shape and size. As a result, operators at this medtech company are forced to stand on the beveled edges, increasing tarsal/metatarsal joint issues.

3. Gaps Between Mats

When your anti-fatigue mats are too small, employees tend to piece together small mats to try and cover their entire workspace. In addition to constant on/off stepping and edge-standing, this multiplies the risk of injury due to gaps between the mats.

Lindsey Kuefler, EHS Manager with The Toro Company, recently dealt with this issue:

According to Lindsey, a team member tripped over pieced together and overlapping mats, breaking their wrist in the process. Lindsey’s team remedied the issue by designing a single custom anti-fatigue mat to fit the workstation. They also standardized their anti-fatigue mat strategy, which is a formal plan communicated facility-wide letting employees know exactly what time of mat they need, what features every mat must have, and where to get them.

This custom 100-1 Series AcroMat shows the "after" Lindsey designed and installed to ensure mat-related injury risks didn't happen again. The custom shapes covers the layout, while the 20-degree, ADA Compliant yellow borders promise a smoother on/off transition.

This custom 100-1 Series AcroMat shows the "after" Lindsey designed and installed to ensure mat-related injury risks didn't happen again. The custom shapes covers the layout, while the 20-degree, ADA Compliant yellow borders promise a smoother on/off transition.

Andy Grunhovd, EHS Manager with Trustile Doors, faced a similar issue:

According to Andy, in his facility longs rolls of mat were being cut and placed next to each other, creating gaps between each mat and constant sliding around because they were “out on an island.”

An employee suffered a rolled ankle when he tripped over two disconnected anti-fatigue mats that were laid next to each other. The operator needed medical treatment and physical therapy, while the company lost money, time and critical production.

Shares to Andy, "replacing the hazardous mats throughout our facility with custom anti-fatigue mats designed to fit each workstation cost less than this single injury."

Left/Before: Pieced together mats resulting in a rolled ankle, lost productivity and worker's compensation.Right/After: Single custom AcroMat mat designed to fit; zero trip hazards from gaps, on/off stepping and edge standing.

Left/Before: Pieced together mats resulting in a rolled ankle, lost productivity and worker's compensation.Right/After: Single custom AcroMat mat designed to fit; zero trip hazards from gaps, on/off stepping and edge standing.

Left/Before: Two mats pieced together creating a trip hazard. Right/After: Single custom AcroMat mat designed to fit.

Left/Before: Two mats pieced together creating a trip hazard. Right/After: Single custom AcroMat mat designed to fit.

Related: Trustile Doors Overcomes Injury with Custom Anti-Fatigue Mats

4. Low morale and engagement

Often overlooked when it comes to finding the right anti-fatigue mats is the mental and emotional health impact when matting situations are perilous.

Musculoskeletal injuries (MSDs), also known as ergonomic injuries, are the No. 1 cause of disability worldwide, and the No. 1 cause of lost or missed work time.

When someone suffers an MSD injury, they are 30-40 times at higher risk of experiencing another (Research Features). Over 15% of workers who experience an ergonomic injury experience depressions as a result (National Library of Medicine).

This is what the cycle looks like:

A. Unsafe work environment causes MSD injury

B. MSD injury increases risk of mental health issues.

C. Mental health issues decrease focus, increasing the risk of future MSD injury.

D. Physical injuries and mental health issues negatively affect productivity.

E. The overall cost to the employee and your company? Exponential.

It’s a cycle that repeats itself over and over until the issue is permanently resolved.

Concludes Mary, “When employees see their employer is invested in giving them the right tools and resources to do their work, there’s a feeling of good will and loyalty. This is significant, especially in industries like manufacturing where retention is a challenge.”

To provide a lift to employee morale, in addition to overall health and safety, American supermarket operator Lunds & Byerly's replaced mats that were too small with a custom semi-circle AcroMat mat precisely designed to fit.

To provide a lift to employee morale, in addition to overall health and safety, American supermarket operator Lunds & Byerly's replaced mats that were too small with a custom semi-circle AcroMat mat precisely designed to fit.

5. Continuous sliding around

Anti-fatigue mats that are too small and left out on an island, like pieced together mats, are more prone to sliding around. Mats that easily slide create a preventable trip hazard.

There are two ways to resolve this problem.

First, shape and size. Custom anti-fatigue mats designed precisely to fit, fit individual workstations like a glove and have nowhere to slide.

Replacing modular tiles that were breaking apart and sliding around, this custom one-piece AcroMat for Andersen Windows wraps fully around the lift table, fitting the workstation like a glove with nowhere to slide.

Replacing modular tiles that were breaking apart and sliding around, this custom one-piece AcroMat for Andersen Windows wraps fully around the lift table, fitting the workstation like a glove with nowhere to slide.

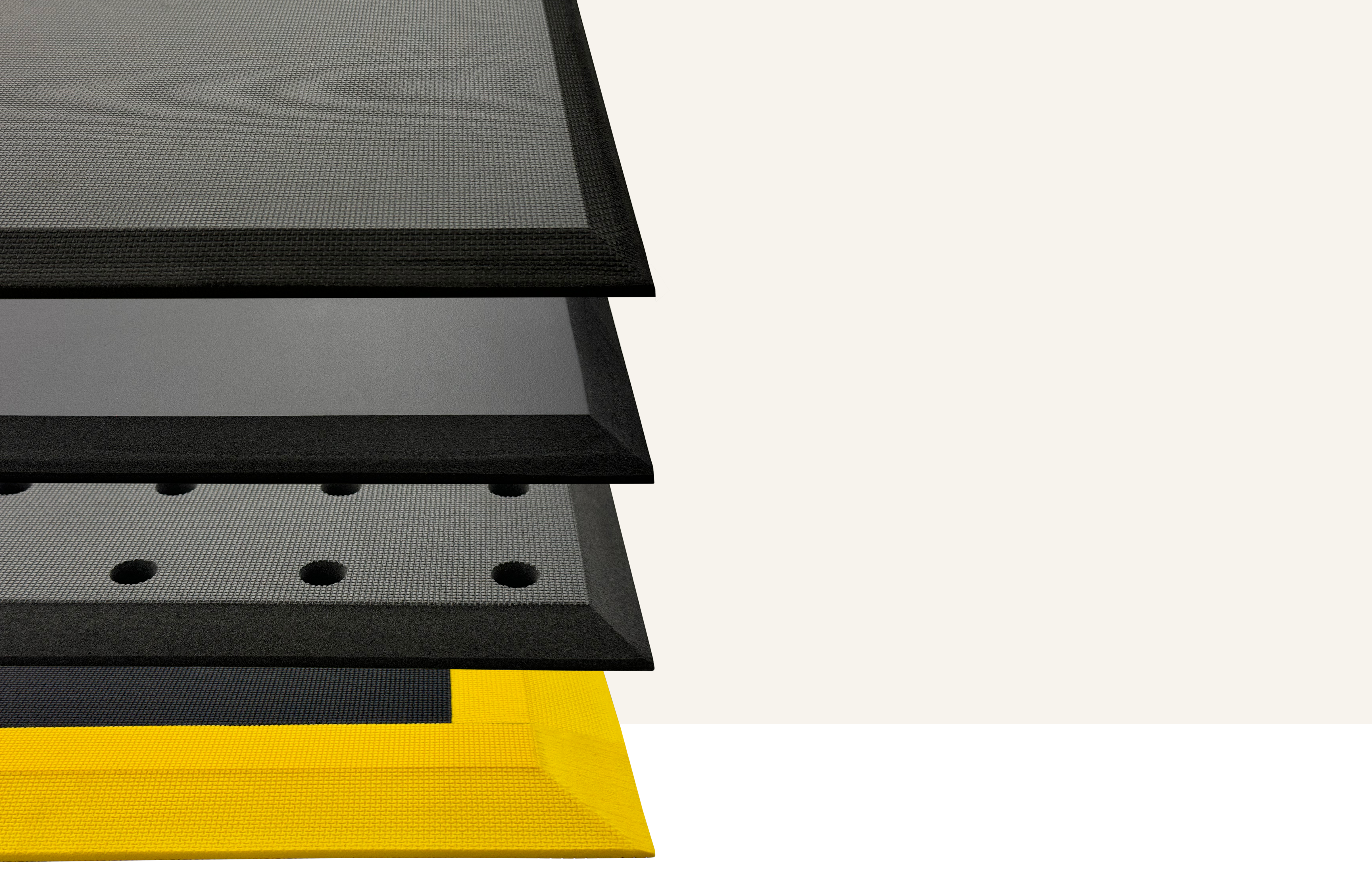

Second, material and non-slip coating. Certain materials, like 100% nitrile rubber foam, more naturally grip the floor in ways PVC foam mats and plastic tiles do not. Combining pure nitrile mats with a non-slip coating is one way to make certain your mats remain in place.

At AcroMat, we manufacture a non-slip coating called Grip-R that can be added to the bottom of any anti-fatigue mat. This water-based material creates a bond between bottom surface of the mat and the floor to keep the mat in place, preventing slip and sliding injury risks.

Grip-R, AcroMat's non-slip coating, is painted or rolled onto the bottom of anti-fatigue mats, multiplying the coefficient of friction between smooth floors and bottom surface of the mat.

Grip-R, AcroMat's non-slip coating, is painted or rolled onto the bottom of anti-fatigue mats, multiplying the coefficient of friction between smooth floors and bottom surface of the mat.

The number of reported MSD injuries is expected to double globally by 2050. There’s a million reasons why MSDs are increasing; your anti-fatigue mats shouldn’t be one of them.

Making sure your anti-fatigue mats are the right size and shape is one way to decrease the risk of pain, discomfort and recordable MSD injuries while also eliminating mat-related slip, trip and fall hazards.

--

Dig Deeper: 10 Signs You Need New Anti-Fatigue Mats

Custom Made Easy: Get to Know the AcroMat Process