Custom anti-fatigue mats are re-shaping workplace safety. At its simplest, "custom" means getting the exact shape and size you need to seamlessly fit your workspace.

This is what we specialize in at AcroMat – making industrial-grade anti-fatigue mats to any size, shape and dimension, whether a simple 2.5 sq. ft. by 3.25 sq. ft. rectangle or sprawling 1,500 sq. ft. mat with curves and cutouts. While the safety benefits are clear, as with any new innovation, there are a lot of misconceptions about custom anti-fatigue mats.

Here are 7 myths about custom anti-fatigue mats – including the truth about how easy, fast, beneficial, and cost-efficient they really are.

Myth #1 – I Don't Need Custom Anti-Fatigue Mats

40% of safety and production leaders say "having to piece together rectangular mats" to cover complex layouts is their No. 1 challenge with anti-fatigue mats. Piecing and piling mats together makes them more likely to slide around, the gaps create trip hazards, and the collection of different mats create inconsistent thicknesses, surfaces and tractions.

It's an antiquated approach that doesn't integrate or keep up with the growing focus on dynamic Lean 5S initiatives spearheaded by today's industry leaders.

Conversely, custom anti-fatigue mats seamlessly designed to fit your workspace eliminate the safety hazards caused by pieced-together solutions. The following three use cases show the benefits of custom in action.

Nokian Tyres replaced pieced-together runners that were cracking, curling, and sliding around with a single custom mat that fits the cell like a glove. The EHS Specialist and three production operators share their experience in this video case study.

Nokian Tyres replaced pieced-together runners that were cracking, curling, and sliding around with a single custom mat that fits the cell like a glove. The EHS Specialist and three production operators share their experience in this video case study.

This manufaucturer was dealing with "rock hard" modular tiles that had to be pieced together, kept coming apart, and were limited to 90-degree configurations. Replacing the tiles with custom mats improved comfort and eliminated multiple trip hazards.

This manufaucturer was dealing with "rock hard" modular tiles that had to be pieced together, kept coming apart, and were limited to 90-degree configurations. Replacing the tiles with custom mats improved comfort and eliminated multiple trip hazards.

Woodward Inc. replaced pieced-together tiles and stacked anti-fatigue mats (increasing the risk of rolled ankles) with one-piece custom mats. The custom mats are now providing consistent comfort and traction throughout each workspace.

Woodward Inc. replaced pieced-together tiles and stacked anti-fatigue mats (increasing the risk of rolled ankles) with one-piece custom mats. The custom mats are now providing consistent comfort and traction throughout each workspace.

Anti-fatigue mats are not a fit in every facility. But if you do use mats, it’s critical you're able to get the sizes and shapes you need to ensure they're working for your people, not against.

Related: 5 Ways Custom Anti-Fatigue Mats Prevent Workplace Injuries

Myth #2 – Custom Anti-fatigue Mats Are Complicated

The need and draw of custom anti-fatigue mats are clear. Yet, there is still hesitancy because the process of getting custom mats for your facility seems complex and arduous. Not anymore.

At AcroMat, we have created an entirely new approach to anti-fatigue mat design. With our proprietary mat building tool, AcroSketch, you (or we) can design the custom mats you need in minutes – any size, shape, and custom features. In brief, AcroSketch has made custom anti-fatigue mats as easy and fast as standard, off-the-shelf matting.

AcroSketch gives users the ability to design their mats to any shape and size to the inch, including curves and circles, logos and custom safety messages, custom borders, even drainage holes and multiple color options.

As daunting as custom may seem, give AcroSketch a try to see how easy it can really be. Further, we are here to assist every step of the way – from leading measurement and design, all the way through delivery and install.

Myth #3 – Custom Anti-fatigue Mats Are Time-Consuming

Similar to anti-fatigue mat design, for years the quoting process for matting has been a multi-week, drawn out process – especially if you have custom design needs.

AcroSketch includes a precise pricing matrix that provides you with an instant quote for any custom anti-fatigue mat project. Our tool charges only by the square footage of material; we do not charge any added labor or customization fees.

We also have many clients who lean on our solution team to visit their facilities, measure their workspaces, and design the custom mats they need. Because of the ease, speed and precision of AcroSketch, we turn quote requests around in 24 hours.

Whether 50 mats or 500, we precision-cut and ship every order within 10 business days directly from our production facility in the Minneapolis Metro. Client: Optum, Inc.

Whether 50 mats or 500, we precision-cut and ship every order within 10 business days directly from our production facility in the Minneapolis Metro. Client: Optum, Inc.

Another consideration is the representative you choose to work with. Some are trained to guide customers towards standard solutions (e.g., 2 ft. by 3 ft. mats) because it’s a quick sale for them. Prioritize what you need, not what they want, then discuss with the actual manufacturer what your options are for a custom solution.

Myth #4 – Custom Anti-fatigue Mats Don't Allow Layout Changes

It’s a misconception that if you have custom mats and your layouts change, they become useless. AcroMat mats are designed to accommodate layout changes. With our repair kit, you can easily re-configure any custom mat on-site with little downtime. We can also make repairs; simply ship your mat back to our team, and we'll re-shape your mat at no cost. You pay only for the material needed.

Further, layout changes happen far less than you might think, and mats do need replacing from time to time. In such case, a layout change every few years can be a helpful reminder that it's time for new anti-fatigue mats.

Layout change? No problem. Re-configure your mat easily with the AcroMat Repair Kit.

Layout change? No problem. Re-configure your mat easily with the AcroMat Repair Kit.

Myth #5 – Custom Anti-fatigue Mats Cost More

For many mat providers, custom anti-fatigue mats do cost more. Not so at AcroMat. We charge purely by the square footage of material. The following use case shows this in action.

A company reached out to AcroMat for a quote. They needed a 4 ft. by 78 ft. custom mat to cover a long assembly area. Yellow borders on all sides. Their operators work 10+ hour shifts, 4 days a week. The manufacturing company originally went to another mat provider.

The response: "I'm sorry, our standard roll is 75'. Do you need it to be 78'?"

The shorter length would leave part of the workspace uncovered, and filling that area with another mat or multiple would create a trip hazard from the gaps. The company said yes it was a need, so mat provider followed up with a quote for both options. The price difference for 3 extra feet of material: $1,400.

In short, a 35% price increase for less than 4% of the mat.

This is highly common with traditional mat providers. They sell pre-cut lengths and widths. Anything outside of standard sizes require additional labor, so they work hard to get you to buy pre-cut sizes. If you do choose custom, they multiply the cost.

The company came to AcroMat, found their mat on our readily available standard-size library, saw instant pricing with no custom fees, and we made and shipped their 4 ft. by 78 ft. anti-fatigue mat a few days later.

150 ft. long custom anti-fatigue mat through winding workspace. Customizing can cost more with the wrong mat provider. It doesn't with AcroMat.

Myth #6 – Custom Anti-fatigue Mats Only Provide Comfort

Custom anti-fatigue mats designed to fit provide seamless comfort and traction. The area is fully covered, so there is no on/off stepping, half on/half off standing, gaps between mats creating trip hazards, or exposed slippery and harsh flooring creating slip hazards.

But comfort and traction aren’t the only benefits. Compared to hard surfaces, nitrile anti-fatigue mats – what we use to make our custom mats here at AcroMat – have proven to reduce head impact injuries by 70% and hip impact injuries 50%.

You can have every preventive measure in place, but sometimes slips, trips and falls will happen. With custom mats covering the entire work area, employees are more likely to land on a soft mat rather than hard concrete or metal grating. This is not the case if you have a handful of 2 ft. by 3 ft. mats pieced and piled together.

When you have a custom mat designed to cover the entire workspace, operators will be less likely to trip. If there is a fall, their bodies will absorb 50-70% less impact.

Myth #7 – Custom Anti-fatigue Mats Break Down Quickly

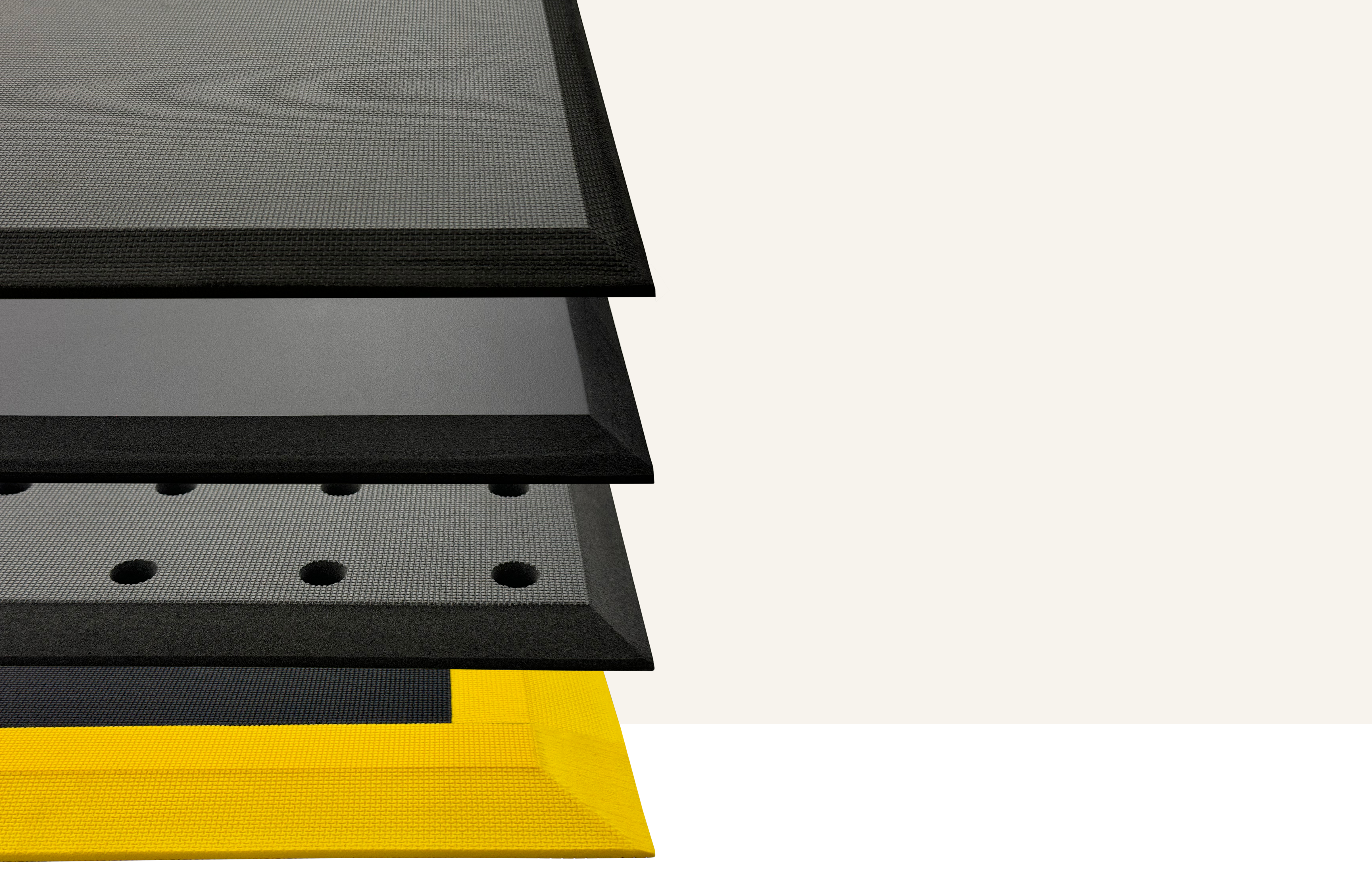

Most anti-fatigue mats are made from extruded PVC foam or a PVC foam/nitrile blend. PVC foam is versatile and less expensive, but it is lacking in a key area: durability. PVC foam mats often sink and lose their ergonomic cushion, and you need to buy new every 6-12 months.

At AcroMat, our anti-fatigue mats are made from closed cell, molded, 100% nitrile rubber foam. Pure nitrile does not include a component of PVC, and is unique in that it never loses its cushion. It’s impervious to liquids, antimicrobial, and because of our design process guaranteed not to curl along the borders. The result is anti-fatigue mats that are designed to last for 3-8 years without issue or interruption.

We back up our claims with a Lifetime Performance Warranty, which promises your mats will never sink, flatten, lose their cushion or curl along the borders, a 100% manufacturing guarantee, and a 60-day moneyback guarantee – covering you from end to end with the protections you need to make sure your mats perform.

It’s true that some anti-fatigue mats are not worth customizing because they don’t have a life expectancy to justify it. With our premium materials, guaranteed to last in even the harshest environments, you can customize with confidence your mats will last.

It’s true that some anti-fatigue mats are not worth customizing because they don’t have a life expectancy to justify it. With our premium materials, guaranteed to last in even the harshest environments, you can customize with confidence your mats will last.

Conclusion

At AcroMat, we are fortunate to partner with some of the world’s leading brands. Industry leaders recognize the value of custom anti-fatigue mats, and they are using our limitless possibilities to elevate health, safety, productivity, even culture in some really fascinating ways.

AcroMat has been serving some of the world's leading brands for over 20 years.

As you weigh your next anti-fatigue mat investment, whether standard sizes or custom anti-fatigue mats designed to fit, make sure you are getting exactly what your people need to get them home from work as healthy as when they arrived.

As we often say, the best mat in the world is worthless if it doesn’t fit the work area.

Get Started: Get a Free Custom Sample Mat