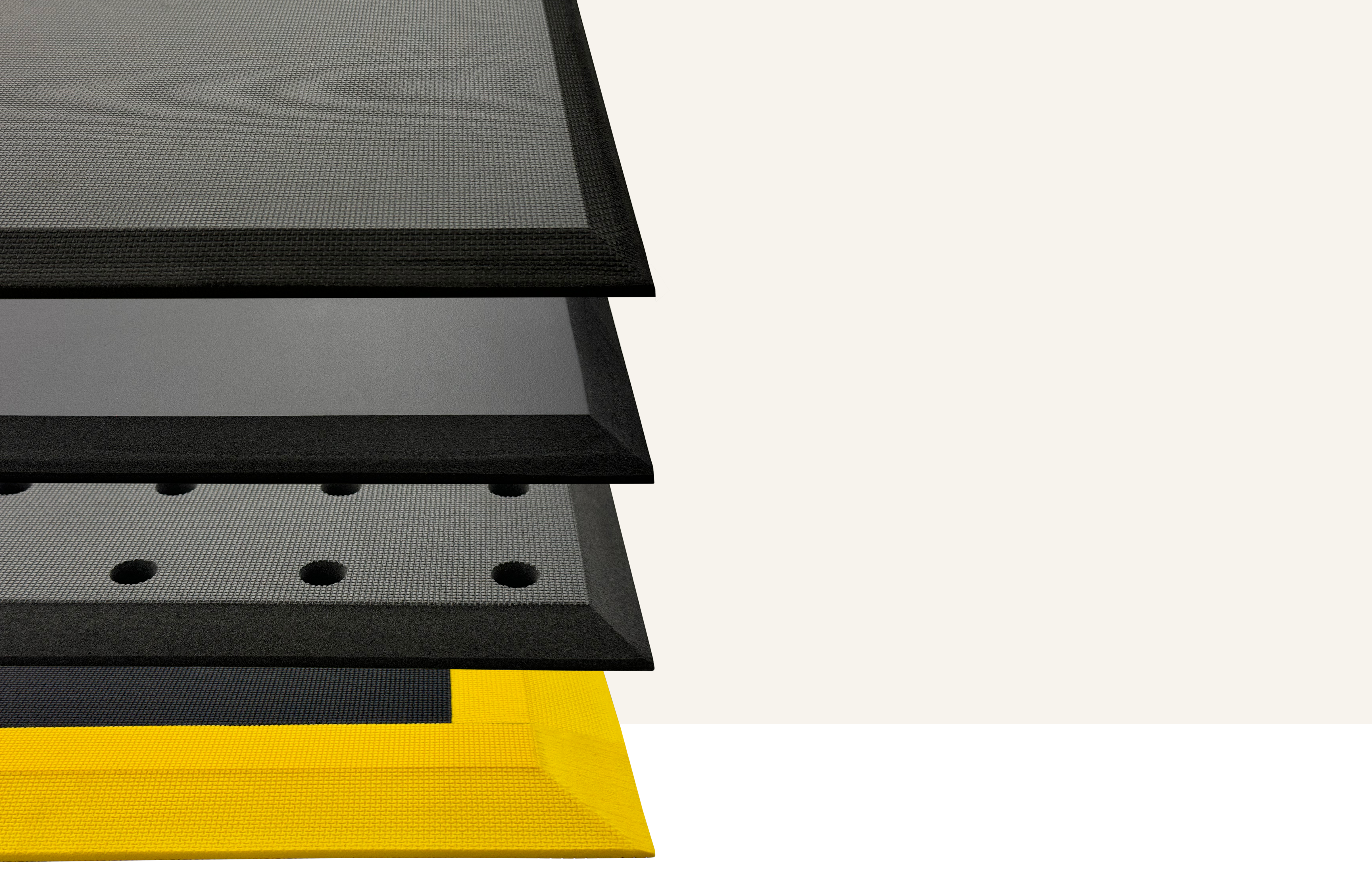

Which safety and ergonomic flooring solution is the right fit for your facility: Modular tiles or custom anti-fatigue mats? Both options offer an important step forward in terms of safety, but there are several key reasons why we recommend one-piece, custom mats precisely designed to fit over snapped-together modular tiles.

If weighing both solutions, here are 7 reasons why we believe custom anti-fatigue mats provide more value and protection than modular tiles.

1. Custom anti-fatigue mats can be made to any shape and size

40% of safety leaders say "having to piece together rectangular mats" to try and cover complex layouts is their main challenge with anti-fatigue mats. Piecing mats together leaves gaps, exposed harsh flooring, overlapping borders and constant on/off stepping – all of which increasing the risk of trip hazards and ergonomic injuries.

The invention of modular tiles set out to eliminate this issue, but they fall short in one key area: Modular tiles are made 12 in by 12 in, 24 in by 24 in, and 36 in by 36 in squares and limited to 90-degree configurations. While they can be "customized" to an extent because of the snap-together features, modular tiles cannot accommodate circles, curves, custom angles, custom border needs, or highly complex layouts.

Before: Modular tiles leave hard, slippery floor exposed and inconsistent borders. After: One-piece custom mats seamlessly cover any layout. Client: Woodward Inc.

Before: Modular tiles leave hard, slippery floor exposed and inconsistent borders. After: One-piece custom mats seamlessly cover any layout. Client: Woodward Inc.

At AcroMat, we have solved this issue entirely. We design, manufacture and precision-cut our anti-fatigue mats to any shape and size in order to create a seamless fit for any layout. Whether a simple 2.5 sq. ft. by 3.25 sq. ft. rectangle or 2,000 sq. ft. with curves, cutouts and custom angles, there is no limit to how you can design your anti-fatigue mats.

We also have a proprietary and freely available online tool, AcroSketch, which gives users the ability to design their custom mats in minutes. Ultimately, rather than snapped-together tiles limited to square configurations, the result is seamless coverage for any layout, without limit.

Before: This facility had to hand-cut their tiles to fit a curved workspace, impacting the structural integrity of the entire system and creating trip hazards. After: One-piece custom anti-fatigue mat seamlessly designed to fit. Client: Woodward Inc.

Before: This facility had to hand-cut their tiles to fit a curved workspace, impacting the structural integrity of the entire system and creating trip hazards. After: One-piece custom anti-fatigue mat seamlessly designed to fit. Client: Woodward Inc.

See a preview of AcroSketch in action. How To AcroSketch is a comprehensive video library that walks users through how to use every feature within the tool, including cutouts, curves, and custom border options.

2. Custom anti-fatigue mats provide easy & fast installation

AcroMat’s custom mats are designed and built as a single piece. The installation includes three quick steps: Unbox, lay out in your facility, and get back to work. We pre-cut our mats to create a perfect fit for your workspace and ensure a simple and quick installation process.

Conversely, modular tiles have to be snapped together – tile by tile, piece by piece. Similar to building blocks, they come with a packet of instructions. Each tile and border is labeled with a number, letter, or both.

Installing modular tiles can be straightforward. However, it does take dedicated time, planning, and often the need to shut down an engine line or work cell for hours at a time.

Modular tiles come with a packet of instructions and have to be installed piece by piece over the course of several hours.

3. Custom anti-fatigue mats provide better ergonomic comfort

AcroMat’s anti-fatigue mats are made from molded, closed cell, nitrile rubber foam. The material provides a medium-soft durometer rating (cushion) and is guaranteed to never sink, flatten or lose its shape – meaning the comfort your operators receive at the beginning will remain unaffected for as long as the mats are in use.

According to Dr. Andrew Laing, Director, Injury Biomechanics and Aging Laboratory with the University of Waterloo, the comfort and stability of nitrile mats can reduce pain and discomfort by up to 50% compared to hard surfaces.

Nitrile anti-fatigue mats can reduce pain and discomfort by as much as 50% compared to hard surfaces like cement, hardwood, and modular tiles.

Nitrile anti-fatigue mats can reduce pain and discomfort by as much as 50% compared to hard surfaces like cement, hardwood, and modular tiles.

The benefits of nitrile anti-fatigue mats extend beyond comfort. AcroMat’s anti-fatigue mats are National Floor Safety Institute (NFSI) Certified for “High Traction” – meaning they maintain their traction in fast-moving environments whether dry, wet, or aging. This has proven to reduce wet-slip risks by 50-90% compared to non-certified surfaces.

Modular tiles, often made from hard plastic or PVC material, fall into the medium-hard durometer rating. Most top-line tile systems will be NFSI Certified for “High Traction,” which is critical, but they don't always provide the comfort employees need.

Before switching to nitrile anti-fatigue mats, operators at the aerospace manufacturer below were stacking mats on top of their tiles to improve comfort. Stacking increases the risk of rolled ankles, creates a preventable trip hazard, and compromises the strength of your posture.

Before: Made from a hard plastic material, modular tiles or ergonomic decking do not provide adequate comfort. This often leads to employees stacking mats for relief.

After: One-piece, medium-soft, custom mat designed to fit. No stacking. According to Dr. Andrew Laing, falling on a nitrile mat can also reduce impact injuries by up to 70%.

After: One-piece, medium-soft, custom mat designed to fit. No stacking. According to Dr. Andrew Laing, falling on a nitrile mat can also reduce impact injuries by up to 70%.

According to Certified Professional Ergonomist, Mary Plehal:

"It's common for stacked anti-fatigue mats to be different sizes, heights and products which creates uneven standing surfaces. This is awkward and exposes employees to a higher risk of slips, trips, falls, and rolled ankles."

"The biggest concern from an ergonomic point of view is that double-stacked mats seem to have subjectively more cushion which is perceived as a good thing. In reality, it creates postural instability that causes the feet, ankles and upwards to the lower back to have to make constant micro-adjustments to maintain balance. This is like working in high heels day after day."

4. Custom anti-fatigue mats have airtight seams

Seam failure is a highly common issue with modular tiles and poorly designed anti-fatigue mats. At AcroMat, new third-party testing shows our seams actually grow stronger over time. CSA Group, formally accredited by OSHA, subjected our molded nitrile 100-Series mats to 4 years of accelerated aging and high-force mechanical pull testing.

The Results: The AcroMat seams not only maintained their integrity after 4 years, but grew stronger from year 1 to year 4 during each mechanical pull test – despite constant exposure to heat, chemicals, and moisture:

Results Summary: Over 4 years of accelerated aging, the seams along the AcroMat 100-Series anti-fatigue mats not only maintained their structural integrity but increased in strength from year 1 to year 4.

Dig Deeper: Mechanical Pull Test Verifies AcroMat 100-Series Seam Strength

Conversely, seams are the No. 1 issue with modular tiles. Because of the puzzle-piece style, there are non-airtight seams along every tile. In heavy industrial settings, chemicals, liquids and particles embed into the seams and pull the tiles apart. This rapidly ages your tiles requiring frequent replacements, the gaps create trip hazards, and broken apart tiles are more likely to slide around creating a slip and fall hazard.

The seams along modular tiles are not airtight and prone to coming apart, especially in heavy industrial settings with particles, chemicals and liquids.

The seams along modular tiles are not airtight and prone to coming apart, especially in heavy industrial settings with particles, chemicals and liquids.

This one-piece custom AcroMat mat is guaranteed (and warrantied) not to weaken, splice, or come apart along the seams.

5. Custom anti-fatigue mats are not at risk of sliding

1 in 5 users are dealing with anti-fatigue mats that slide around – a clear and present safety hazard. The average slip and fall injury claim is $50,000 and 12 missed workdays.

Custom anti-fatigue mats can be tailored to any shape or size, ensuring a glove-like fit and full coverage of your workspace. When your mats fit the work area perfectly, they have nowhere to slide. Custom mats can also be reinforced with a non-slip coating.

EHS Specialist Amanda Eskew with Nokian Tyres shares how AcroMat's custom mats combined with our Grip-R Non-slip Coating have eliminated sliding and improved morale throughout their 500+ person facility.

Modular tiles are limited to strict lengths and widths. In the facility below, because of the rigid length/width options, the tile system doesn't fit the work area. This leaves hard and slippery concrete exposed, and has led to the tiles sliding around.

Left: Broken and sliding modular tiles, creating safety and ergonomic hazards. Right: One-piece custom anti-fatigue mat. The glove-like fit eliminates any threat of sliding.

6. Custom anti-fatigue mats improve aesthetic

Workplace aesthetic is an overlooked but key benefit of custom anti-fatigue mats. Aesthetic has proven to impact satisfaction, mental health and productivity.

According to Emerald Technologies:

"Aesthetically pleasing interiors reduce stress ... When workers are forced to work in dreary or dysfunctional offices, it can increase stress levels and reduce productivity."

According to Leitz:

"A drab and unwelcoming space has a negative impact on how productive we are. On the other hand, when a space has been designed thoughtfully, people feel more welcomes and more motivated to work."

Too often, safety flooring solutions are a plight on the workplace. They are ripped and torn, cracked, only half-covering a workspace, coming apart at the seams, and strewn about. Whether intentional or not, this sends a clear message to job candidates, long-tenured employees, and your clients.

Custom anti-fatigue mats – that is, high-quality mats precisely designed to fit your workspaces – can significantly elevate aesthetic.

"Just wanted to say how well your mats do for us from a 5S standpoint: Sort, Straighten, Shine, Standardize, and Sustain. Not only worker safety but also aesthetics!"

"Just wanted to say how well your mats do for us from a 5S standpoint: Sort, Straighten, Shine, Standardize, and Sustain. Not only worker safety but also aesthetics!"

–Adam Arnold, Senior EHS Manager, Daikin Applied

Tiles can likewise elevate aesthetic in the right situations. Yet, when areas are only half covered because of shape limitations, operators are stacking mats on top of their tiles, and tiles seams are coming apart and creating trip hazards, aesthetic is not only impacted but the issues communicate to employees that their safety may not be a priority.

7. Custom anti-fatigue mats have a performance warranty

Modular tiles and ergonomic decking are often covered under a "manufacturer's warranty," which promises the tile pieces will be made without defect. However, we are not aware of any tile systems that are covered under a performance warranty.

For example, this is directly from a "lifetime" warranty from a global tile manufacturer: "Installing may void the warranty ... Does not apply to custom made flooring, loss or normal wear and tear ... The decision to void this warranty will be made at the sole discretion of [Company X]."

In other words, the moment you unbox and install your tiles, you are left without protections should they fail to perform.

Left: Curling borders and broken seams are not covered under warranty, leaving this facility without protection. Right: AcroMat guarantees and warranties your anti-fatigue mats will not curl, sink, flatten or come apart.

Left: Curling borders and broken seams are not covered under warranty, leaving this facility without protection. Right: AcroMat guarantees and warranties your anti-fatigue mats will not curl, sink, flatten or come apart.

At AcroMat, our anti-fatigue mats come with a manufacturer's guarantee and lifetime full-replacement performance warranty. Our risk-free warranty guarantees:

- The edges of your mat will NEVER curl.

- The mat will NEVER flatten or lose its ergonomic cushion.

- The bonds along your mat will NOT come apart.

If any of these issues happen to your custom anti-fatigue mats, we are responsible for replacing them and your team is fully protected. If the same issues happen to your modular tiles, you are left with the option of enduring the hazards or replacing them on your own dime.

--

As an anti-fatigue mat manufacturer, we provided hundreds of safety assessments every year. If weighing either custom anti-fatigue mats or modular tiles in your facility, ask these 5 questions before making any firm decisions:

1. How long will the mat/tile material hold up in our environment?

2. Will the mat/tile material provide the ergonomic comfort we need?

3. Are the mat/tile seams airtight? Is there a threat of them breaking apart?

4. Are weaking, splicing or seams coming apart covered under the warranty?

5. Will the mats/tiles leaves harsh floor in the workspace exposed for our employees

Take Action: Get a Free AcroMat Sample Mat Today

More Custom Examples: Custom Anti-Fatigue Mat Gallery