CASE STUDY

Iowa Molding Tool Eliminates Mat-Related Trip Hazards

Challenge

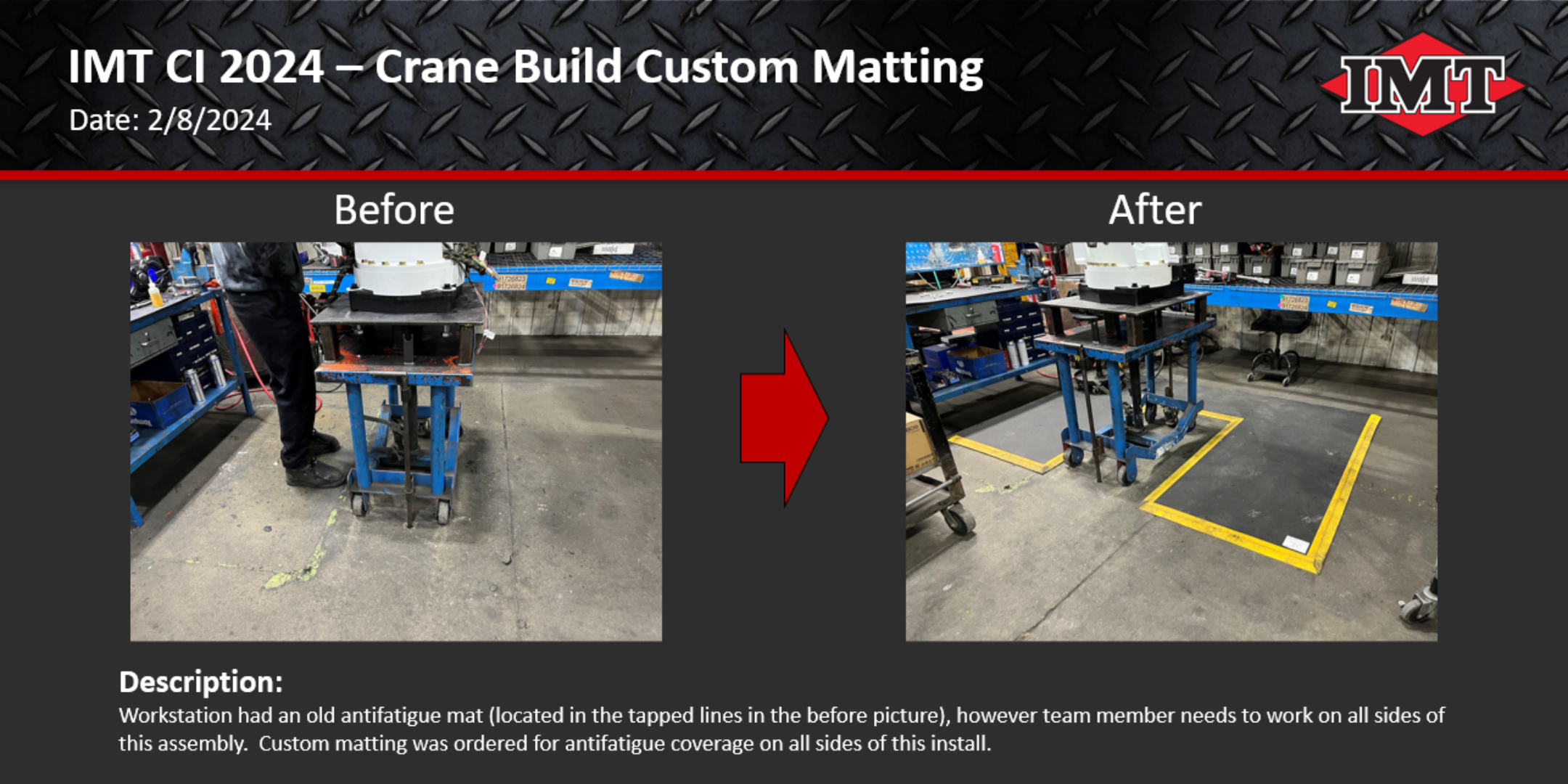

EHS Manager Ryan Fischer at Iowa Mold Tooling Co. (IMT), Inc. shares how his team put a permanent end to anti-fatigue mat-related trip hazards with custom mats designed to fit.

IMT designs and manufactures mechanics trucks, lube trucks, air compressors, and truck-mounted cranes. To build these products, IMT employees stand long hours and move back and forth across their work cells regularly.

The team at IMT was previously filling workspaces with a random assortment of mats. The piecemeal approach left gaps between mats, caused ergonomic issues, and forced machine operators to constantly watch their feet rather than focus on the work.

Our operators were pushing their anti-fatigue mats to the side, a lot of times preferring no mats at all compared to the hodge-podge we had before.

Before: IMT was using several styles of mat – each with different thicknesses, surfaces and edges. Out on an island, the mats also slid around. Collectively, this created trip and slip hazards, and ergonomic inconsistencies.

After: IMT replaced the "hodge-podge" mats with one-piece custom anti-fatigue mats designed to seamlessly fit each workspace, creating a consistent surface, cushion and traction, and eliminating mat-related trip hazards.

Solution

Key Results:

- IMT eliminated mat-related trip hazards with custom mats designed to fit

- IMT put an end to curling borders with strategic mat design and materials

- IMT relied on a thorough trial process to ensure AcroMat was the right fit

- IMT saved thousands of dollars with mats that last years instead of months

- IMT employees are more engaged with mats that protect their well-being

Custom Design Eliminates Trip Hazards

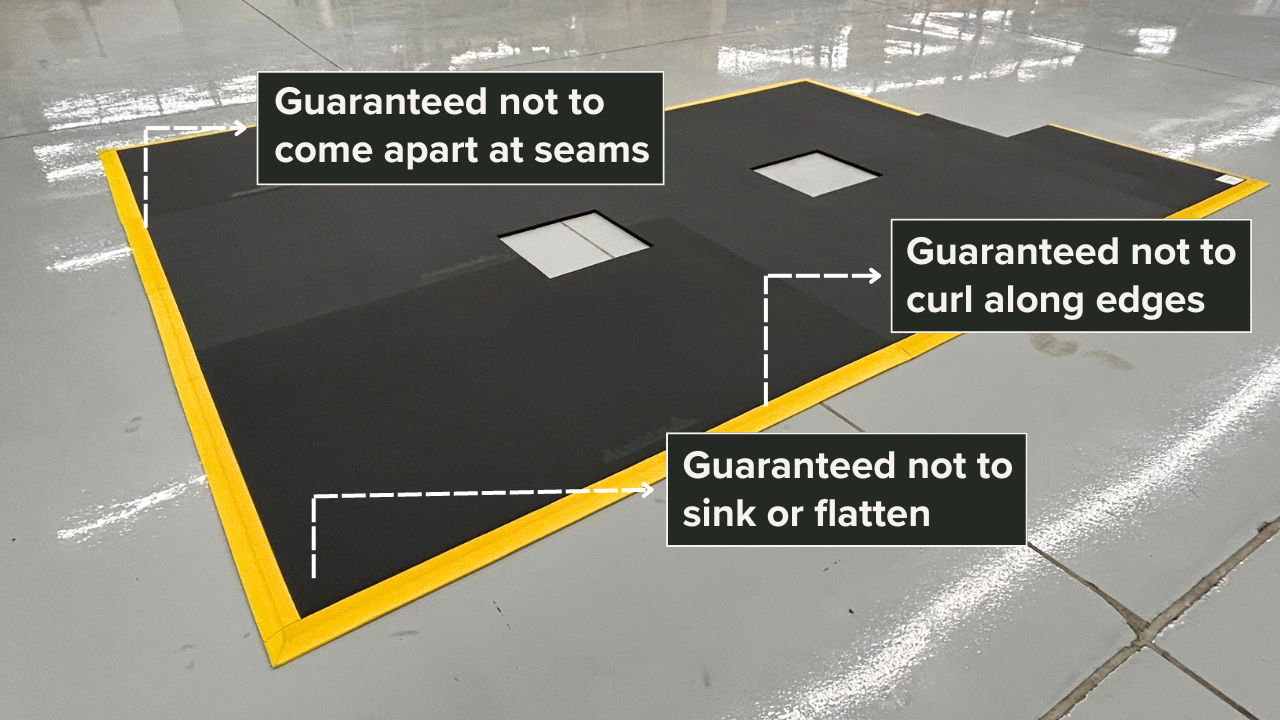

In partnership with AcroMat, IMT replaced the random and haphazard mats with custom mats designed and precision-cut to fit each individual workstation – eliminating the need to piece mats together and the mat-related tip hazards caused by gaps and constant on-off stepping.

The custom mats provide each workstation with consistent cushion and thickness, and a National Floor Safety Institute “High Traction” Certified surface which has proven to reduce wet-slip risks by 50-90%.

The custom-cut shapes, combined with 100% nitrile rubber foam which is engineered to endure even the harshest environments, are now providing operators with an average of 5 years of uninterrupted support compared to the months they were getting before.

A Permanent End to Curling Edges

Made from PVC foam, IMT’s previous mats were buckling and breaking down when met with oils and other harsh liquids. The buckling combined with the "waterfall" designed mats allowed the edges to lift off the ground, creating trip hazards throughout the facility. This also rendered the mats usefless and required new mats, taxing the safet budget.

AcroMat uses an exclusive cut-and-bond design combined with a material that’s impervious to liquids and chemicals. The collective approach allows AcroMat to guarantee and warranty non-curling edges.

Extensive Sample Process

IMT had a limited budget for anti-fatigue mats, and couldn’t afford to start over with their matting every few months. They needed mats that would hold up for years at a time without interruption, and guarantees their investment would be protected.

Ryan was previously with Winnebago Industries, where he played a key role in a project between Winnebago-AcroMat involving the design of 300 custom mats.

With Winnebago, Ryan tested AcroMat mats over several months to make sure they held up in a heavy manufacturing environment. After Winnebago saved $150,000 over 5 years because of better durability, Ryan brought this information to IMT when he joined and shared AcroMat's 2-year full replacement warranty.

The AcroMat warranty guarantees:

- Your mats will NOT buckle or curl along the borders.

- Your mats will NOT weaken or come apart at the seams.

- Your mats will NOT flatten or lose its ergonomic cushion.

With AcroMat’s no easy-outs, performance warranty – protecting IMT from the most common issues anti-fatigue mat users face – leadership knows with certainty their people and budget are secure.

Featured Products

SOLUTIONS BUILT FOR YOUR ENVIRONMENT

100-1 Series

LEARN MORE

NitriTuf Diamond Series

Learn More